https://flipbooks.fleepit.com/f-94886-clickbrick_rapid_shelter_deployment

https://flipbooks.fleepit.com/f-94886-clickbrick_rapid_shelter_deployment

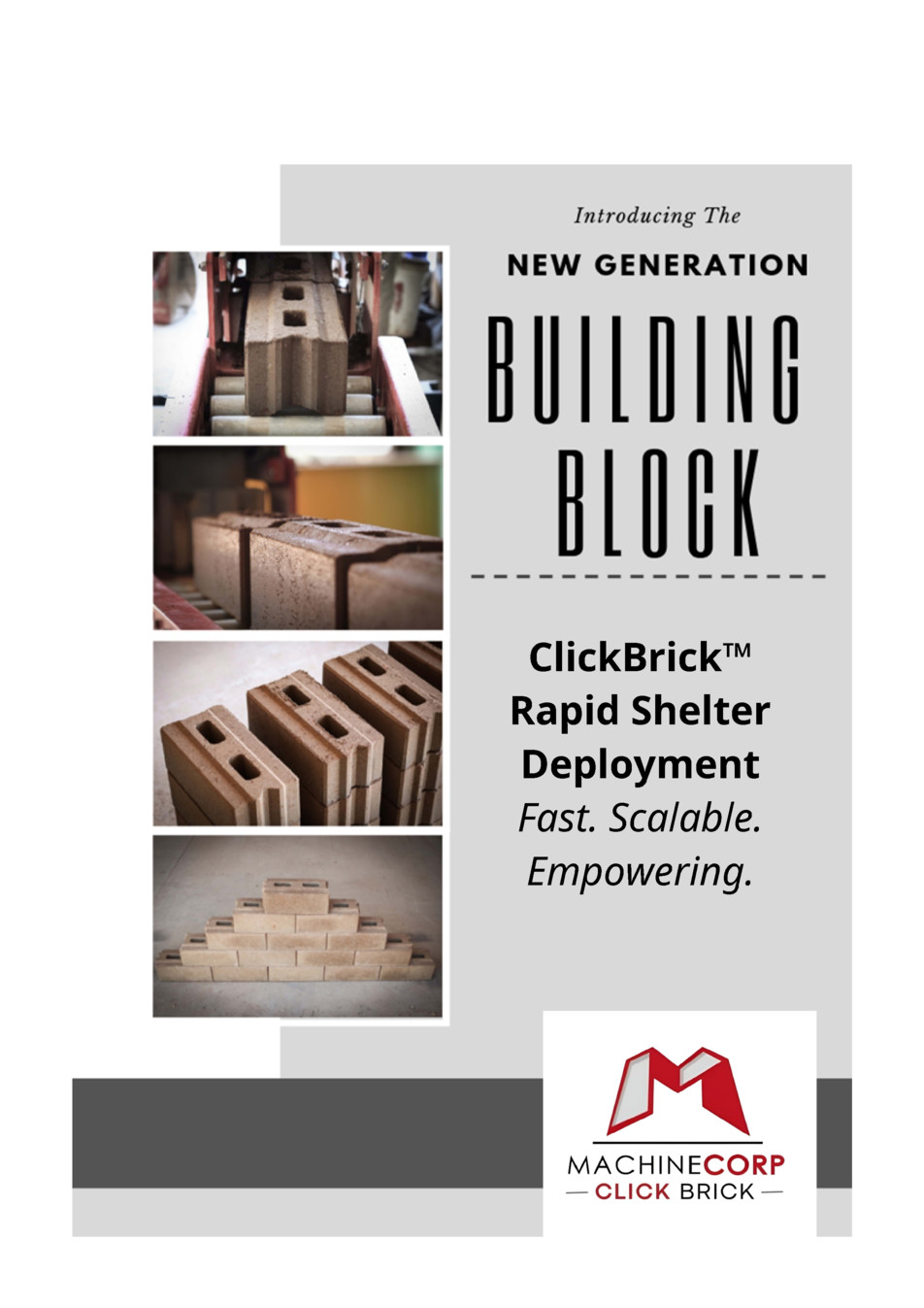

ClickBrick™ Rapid Shelter Deployment

Overview

In response to a humanitarian crisis, ClickBrick™ partnered with NGOs to provide rapid and dignified shelter for displaced families. Leveraging their Turnkey Container Plant, they enabled fast and efficient construction using local resources and empowering community labor. The main objectives were to complete 20m² 1-bedroom units in under 24 hours, provide onsite training using a mobile plant, minimize the need for imported materials by utilizing local soil and water, and ensure dwellings are durable, thermally efficient, and upgrade-ready (p.2).

Features of Turnkey Container Plant

The Turnkey Container Plant is a self-contained 20ft container that includes a Rotary Sieve, Mixer, Conveyor, and Hydraulic Brick-Making Machine. It also has a 3-Phase Generator that is grid-compatible, requires minimal skilled labor, and enables onsite production of interlocking ClickBricks™ (p.2).

Shelter Snapshot and Advantages

Each shelter unit consists of ClickBricks, cement for walls, locally sourced soil, water, slab concrete, sand, aggregate, and optionally steel mesh based on soil condition. The advantages of the ClickBrick houses include one-day build time, eco-friendliness due to low cement use and minimal waste, mobility and scalability for remote areas, empowerment of labor and local training, upgrade-ready modular design, and skill development through on-the-job learning (p.2).

https://flipbooks.fleepit.com/f-94886-clickbrick_rapid_shelter_deployment - Flipbook by Fleepit