Rapid Shelter Deployment Fast. Scalable. Empowering.

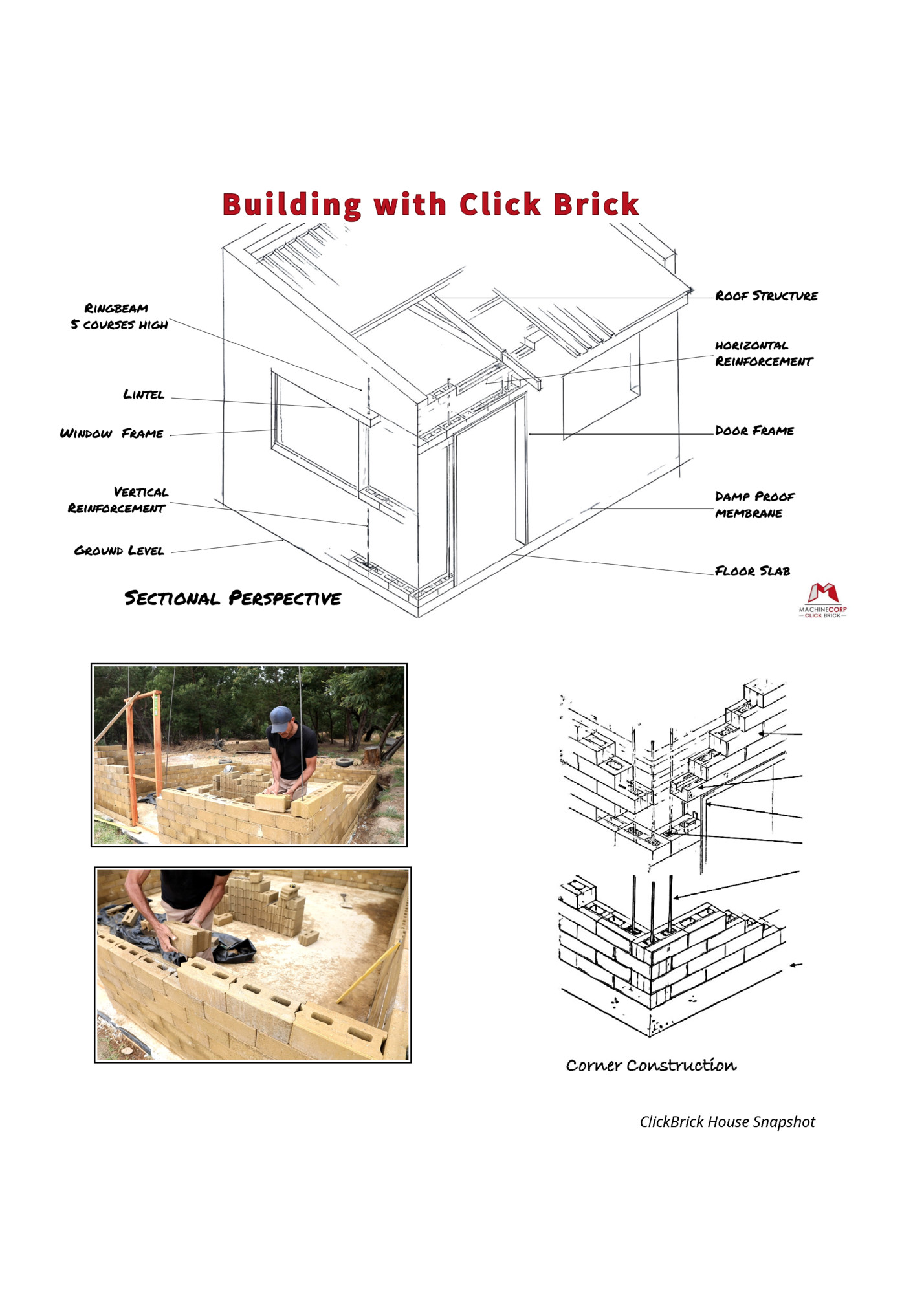

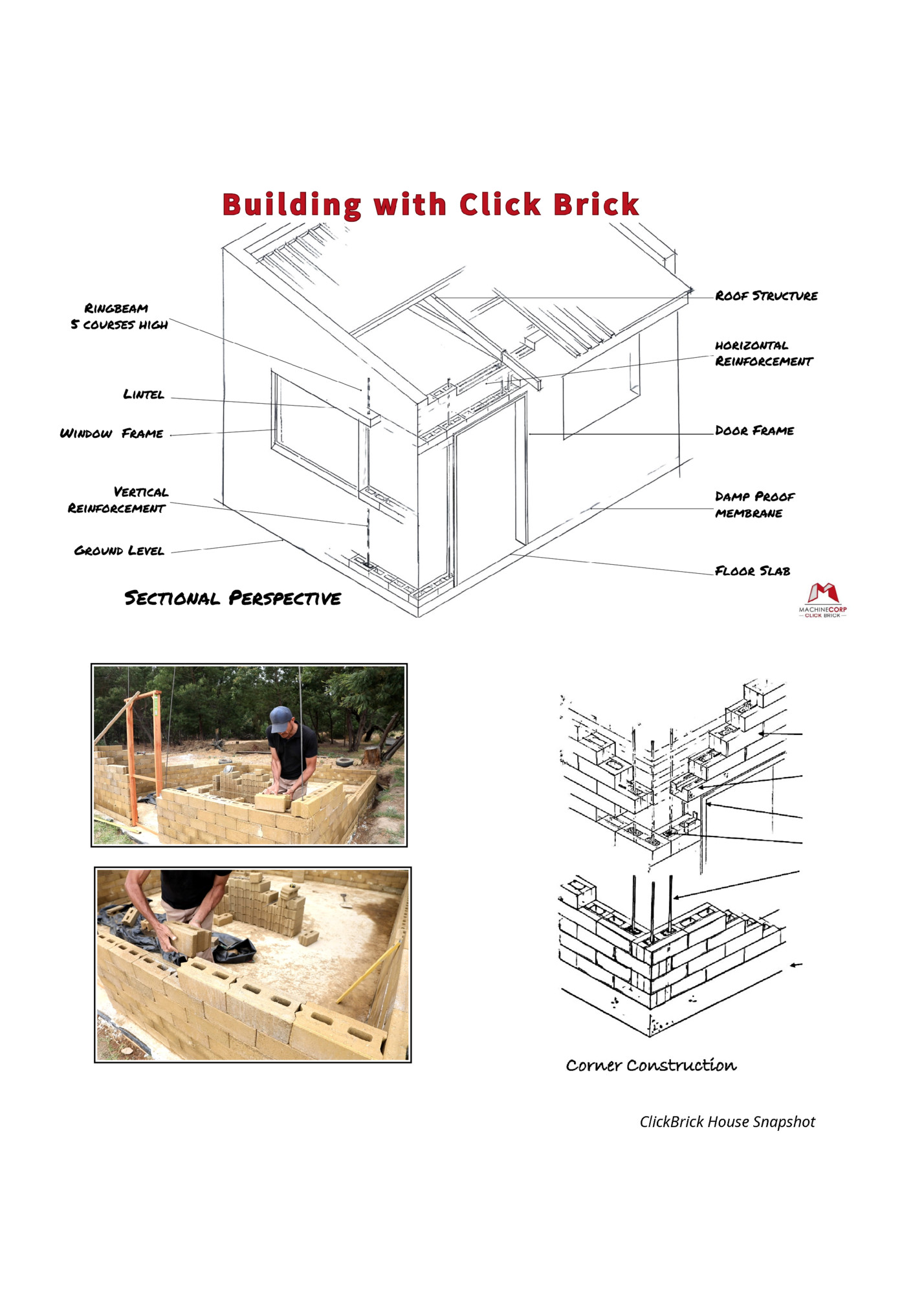

Emergency Housing Relief with ClickBrick™ Technology CONTEXT: In response to a humanitarian crisis, ClickBrick™ partnering with NGO’s to provide rapid, dignified shelter for displaced families. Leveraging our Turnkey Container Plant, we enabled fast, efficient construction using local resources and empowering community labour. OBJECTIVES: Complete 20 m² 1-bedroom units in under 24 hours Provide onsite training using our mobile plant Minimize need for imported materials by using local soil & water Ensure dwellings are durable, thermally efficient & upgrade-ready TURNKEY CONTAINER PLANT FEATURES: Self-contained 20ft container Includes: Rotary Sieve, Mixer, Conveyor & Hydraulic Brick-Making Machine 3-Phase Generator (grid-compatible) Requires minimal skilled labour Enables onsite production of interlocking ClickBricks™ SHELTER SNAPSHOT (PER UNIT): ClickBricks (8MPa): ±1410 Cement (Walls): ±30 bags (50kg) Soil: ±7.5 m³ (locally sourced) Water: ±800L (10% compaction ratio) Slab Concrete: ±2 m³, 100mm thick (25MPa) Sand: ±1.2 m³ • Aggregate: ±2.4 m³ (19mm) Optional: Steel Mesh based on soil condition

One-day build Eco-friendly: Low cement use, minimal waste Mobile and scalable for remote areas Labour empowerment and local training Upgrade-ready modular design Skill development through on-the-job learning OUTCOMES: 42 units built in 2 weeks — sheltering over 170 people Costs cut by 40% vs conventional builds Created local jobs and transferable construction skills Developed a scalable model for future relief and housing needs CLICKBRICK™ | Build Smarter. Live Stronger. www.clickbricksa.com | info@clickbricksa.com

Rapid Shelter Deployment Fast. Scalable. Empowering.

Emergency Housing Relief with ClickBrick™ Technology CONTEXT: In response to a humanitarian crisis, ClickBrick™ partnering with NGO’s to provide rapid, dignified shelter for displaced families. Leveraging our Turnkey Container Plant, we enabled fast, efficient construction using local resources and empowering community labour. OBJECTIVES: Complete 20 m² 1-bedroom units in under 24 hours Provide onsite training using our mobile plant Minimize need for imported materials by using local soil & water Ensure dwellings are durable, thermally efficient & upgrade-ready TURNKEY CONTAINER PLANT FEATURES: Self-contained 20ft container Includes: Rotary Sieve, Mixer, Conveyor & Hydraulic Brick-Making Machine 3-Phase Generator (grid-compatible) Requires minimal skilled labour Enables onsite production of interlocking ClickBricks™ SHELTER SNAPSHOT (PER UNIT): ClickBricks (8MPa): ±1410 Cement (Walls): ±30 bags (50kg) Soil: ±7.5 m³ (locally sourced) Water: ±800L (10% compaction ratio) Slab Concrete: ±2 m³, 100mm thick (25MPa) Sand: ±1.2 m³ • Aggregate: ±2.4 m³ (19mm) Optional: Steel Mesh based on soil condition

One-day build Eco-friendly: Low cement use, minimal waste Mobile and scalable for remote areas Labour empowerment and local training Upgrade-ready modular design Skill development through on-the-job learning OUTCOMES: 42 units built in 2 weeks — sheltering over 170 people Costs cut by 40% vs conventional builds Created local jobs and transferable construction skills Developed a scalable model for future relief and housing needs CLICKBRICK™ | Build Smarter. Live Stronger. www.clickbricksa.com | info@clickbricksa.com

Fleepit Digital © 2021