Layers A Technical Handbook on Metal Composite Panels Volume 1.0

add something which cannot be bought or measured with money” - Sir M Visvesvaraya

Handbook ABOUT ALUDECOR Since its inception in 2004, Aludecor has remained a premium ACP sheet manufacturer in India, synonymous with trust and reliability. Aludecor Metal Composite Panel is the number one choice of Architects, Facade Technicians, and Space Designers. With a passion for innovation, Aludecor has maintained its stature in the Indian ACP Manufacturing Industry as a Thought Leader. The Company’s end-to-end Aluminium Composite Panel Manufacturing portfolio is powered by a 500+ strong retail network. A presence in more than 250 cities and world-class Manufacturing Units in Haridwar, empower Aludecor to keep on introducing breakthrough products that have been creating benchmarks in the market for the past 15+ years. As a “Made in India” brand, Aludecor produces all its ingenious products in-house. The Product Units support the Company with a production capacity of 5.5 million square meters per annum. An unshakeable commitment towards excellence has also let Aludecor cater to famous National and International clientele such as Hyundai, KFC, Toyota, Samsung, Tanishq, Aditya Birla Group, Amul, Maruti, Jaguar and many more. Aludecor’s ultimate commitment lies in holding forth its mission as an ethical and “green” company.

Facades At Aludecor, we understand facade beautification and installation technologies like no other. A passion for innovation drives us to achieve the most mesmerizing facade designing through break- through, contemporary facade installation technologies. Through this Technical Manual Book, we look forward to sharing with you, the best insights of the MCP Facade Installation Industry. We have curated intricate details via this piece of literature to help you engage better with your dream projects. Unleash your creative spirit with us today!

Handbook INDEX 1. Introduction to Metal Composite Panels 2. Aluminium and Aluminium Alloys Chapter 1 3. Zinc & Copper Chapter 3 4. Coil Coating/Paint Chapter 4 13 5. Core Chapter 5 19 6. Design Guidance Chapter 6 25 7. Fabrication Guidance Chapter 7 45 8. Aludecor Systems Chapter 8 57 9. Cleaning, Maintenance Chapter 9 61 Chapter 2 01 05 11 & Product Handling Annexure 1 : EN 573 and EN 485 67 Annexure 2 : TDS of Products 85 Annexure 3 : EXOVA Test Certificates 107

Introductio n to Metal Composite Panels

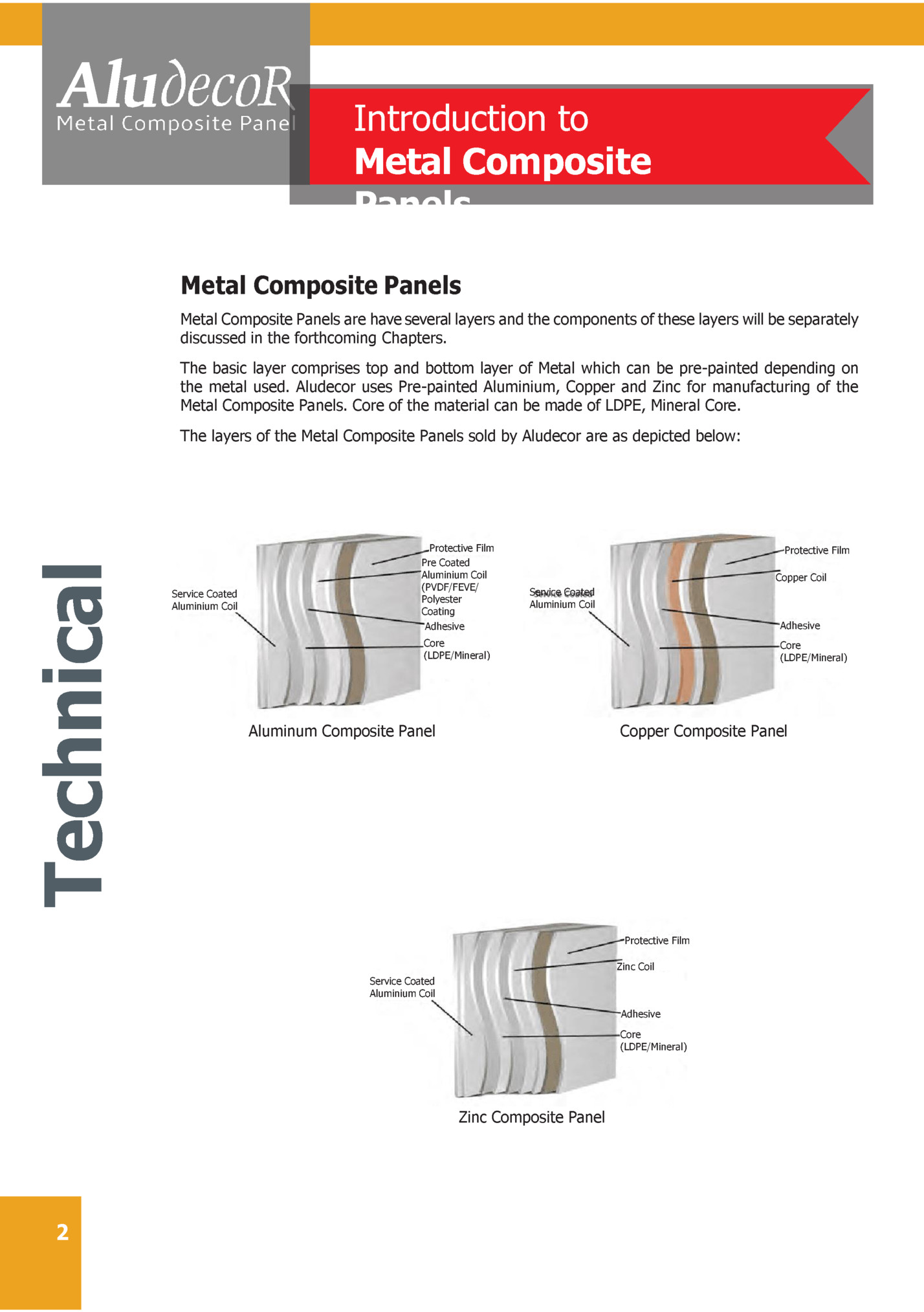

Metal Composite Panels Metal Composite Panels Metal Composite Panels are have several layers and the components of these layers will be separately discussed in the forthcoming Chapters. The basic layer comprises top and bottom layer of Metal which can be pre-painted depending on the metal used. Aludecor uses Pre-painted Aluminium, Copper and Zinc for manufacturing of the Metal Composite Panels. Core of the material can be made of LDPE, Mineral Core. Technical Handbook The layers of the Metal Composite Panels sold by Aludecor are as depicted below: Service Coated Aluminium Coil Protective Film Pre Coated Aluminium Coil (PVDF/FEVE/ Polyester Coating Adhesive Protective Film Copper Coil Service Coated Aluminium Coil Adhesive Core (LDPE/Mineral) ) Aluminum Composite Panel Core (LDPE/Mineral) ) Copper Composite Panel Protective Film Zinc Coil Service Coated Aluminium Coil Adhesive Core ) (LDPE/Mineral) Zinc Composite Panel 2

Technical Handbook Advantage Aludecor MCP Metal Composite Panels are the best metal cladding products in terms of precision and consistency. Research studies on MCPs claim that it stays flat after installation. It requires no oil canning or wrinkling as the skins in it are bonded to the cure under tension producing a balanced panel. MCPs are not only flat but also provide a consistent finish. Besides, MCPs can provide finishes in any colour as per the desires of the building owner or Architect. On the other hand, the natural unfinished look of Zinc and Copper also provide the added benefit, natural to these products. The advanced paint technologies used in the MCP manufacturing process, eliminates the possibility of a checkerboard visual effectively on the exterior of the building. It ensures consistent finish from one to the next. 2. Unparalleled Brilliance and Highest Gloss Retention Steel Applicator Roll at Aludecor's in-house state-of-the-art coating line, a technology of the highest international standard, ensures unparalleled brilliant effects in our metallic shades contrary to the out- put through the widespread use of rubber roller system in the industry. Internationally accepted FEVE and 70:30 ratios of the PVDF and acrylic resins in PVDF coating (the PVDF resin is of Kynar 500 / Hylar 5000) ensures the highest gloss retention in Aludecor MCPs. 3. Lead Free If ACPs are not coated with lead-free paints, one can be exposed to the menace of lead poisoning. The infection can also get spread to others, and children are the most vulnerable. Long-term exposure to the highly carcinogenic lead affects the lungs, kidneys, liver and the nervous system. Use of lead-free paints in Aludecor’s coating line successfully eliminates the possibility of lead poisoning. 4. Best Workability, Flexibility and Minimal Crack Risks The Aluminium coils sourced in Aludecor are made with Direct Chill (DC) processed aluminium alloy ensuring best elongation property, finishing, flexibility and workability. It also minimizes the risk of cracks. 5. Innovation Quotient Aludecor offers a versatile range of unique and patented digital technology enabled finishes and designs. Robust in-house R&D is backed by best international quality labs. 6. Double Coat Double Bake Line It is a continuous and single line process that ensures zero elongation cracks on primer and paint sur- face. It also results in better bonding. Aludecor’s Double Coat Double Bake Line is a pioneering initia- tive in India that enhances the longevity of ACPs in severe weather conditions. 7. Excellent Fire Fighter Aludecor FireWall is process certified for Reaction to Fire by ewcl 5 as per EN 13501-1, Class A2-s1, d0 ClassB-s1, d0 and BS 476 Part 6 and 7 Class O. Aludecor FireWall has also passed the ASTM E119-12 test for 2-hour resistance to fire. The test also

Fleepit Digital © 2021