BORELINE FLEXIBLE RISING MAIN INSTRUCTIONS FOR USE & TECHNICAL INFORMATION Issue Number: 29 Dated: Jan 2022 Manufactured By Hose Manufacturers Micro Street, Triangle Estate, 7530 Telephone: +2721 948 3971 Business WhatsApp: +27 64 823 0763 messages only Website: www.hosessa.com Email: sales@hosessa.com EN ISO 9001 : 2015 REGISTRATION No. 44 100 161428 Boreline Instructions For Use & Technical Information -1 Issue Number: 29 Jan 2022

Boreline Instruction & Technical Manual CONTENTS Introduction to BORELINE......................................................................................................... 3 Rising Mains .......................................................................................................................... 3 Corrosion and Scaling ........................................................................................................... 3 System Efficiency .................................................................................................................. 4 Description ............................................................................................................................ 5 Product Approval ................................................................................................................... 5 Specifications............................................................................................................................ 6 The Riser .............................................................................................................................. 6 Riser Specifications ............................................................................................................... 6 Couplings .............................................................................................................................. 6 Benefits of BORELINE........................................................................................................... 7 Applications ........................................................................................................................... 7 Storage and Handling ............................................................................................................ 7 Disposal ................................................................................................................................ 7 Safety.................................................................................................................................... 7 Hazards................................................................................................................................. 8 BORELINE Installation / Retrieval Procedure ........................................................................... 9 Installation : Before you Start ............................................................................................. 9 Fitting the BORELINE coupling and Riser to the Pump ................................................... 10 Fitting the Power Cable ..................................................................................................... 10 BORELINE Installation Procedure using a VEHICLE ........................................................... 13 BORELINE Retrieval Procedure using a VEHICLE .............................................................. 14 BORELINE Installation Procedure using a CRANE .............................................................. 15 BORELINE Retrieval Procedure using a CRANE ................................................................. 16 Boreline Questions & Answers ................................................................................................ 17 Appendix 1 .............................................................................................................................. 20 Cable Strap Clove Hitch ...................................................................................................... 20 Appendix 2 .............................................................................................................................. 21 Polyurethane Resistance Table ........................................................................................... 21 Boreline Instructions For Use & Technical Information -2 Issue Number: 29 Jan 2022

Introduction to BORELINE Boreline is manufactured in South Africa by Hose Manufacturers, a Company established in early 1960 and specialising in the manufacturer of fire, industrial, mining, and agricultural hoses. Introduced in 1993, Boreline synthetic flexible riser has proved itself throughout Africa, Australia, North and South America, Europe and in parts of the Middle East for smooth and cost-effective borehole pump installation. Easy to install and retrieve, Boreline is designed as a long lasting replacement for steel riser pipes, which in aggressive water conditions are prone to rust and encrustations. Boreline has been tested in accordance with the methods specified in BS 6920: Part 2: 2014. Boreline has NSF / ANSI Std 61 AWWA approval for drinking water system components which can be confirmed on Totally resistant to corrosion, this riser also benefits from an unrivalled choice in couplings available in a wide range of sizes and materials. (Including a Glass Reinforced Nylon version for the smaller sizes.) Extremely cost-effective and with very little downtime or maintenance required, Boreline is made from exceptionally strong, high tenacity yarns and thermoplastic materials which provide superior durability. Rising Mains Steel Risers have historically been used for borehole rising mains. They are generally available in 3m or 6m lengths with sizes 1½” to 3” being screwed together, while 4” and above are usually flanged & bolted. As a protection against corrosion these pipes are galvanized or epoxy-coated but such coatings have proven not to be 100% effective in protecting the steel. The slightest damage to the coating can be a source of localised corrosion, while screwed and flanged joints are always susceptible to corrosion. Due to their weight and size, steel pipes require large vehicles for transportation and handling can be awkward in confined spaces. Boreline is a Flexible Rising Main that has been designed to benefit the user in the long term. It simplifies the work involved in installing and removing submersible pumps. Constructed of high tenacity polyester yarns with an inner and outer coating of polyurethane, the product provides excellent resistance to abrasion resulting in a durable product that has already proved itself worldwide. Boreline is lightweight, flexible and flat and is supplied in compact rolls. It is easily stored and handled in comparison to steel and conducive to safe working conditions. Boreline is available in any continuous lengths of up to 300m up to 2”), 200m up to 6” and 120m in 8”. At the pump end the patented double-ring coupling is screwed into the non-return valve and attached to the hose. On the upper end the coupling screws into the base plate or head works. This simple operation greatly reduces the installation or retrieval time of the system. Less labour is also required. Corrosion and Scaling Boreline is totally resistant to corrosion, scaling and biological growth. Corrosion affects steel risers and therefore their strength, while internal scaling or encrustation affects the efficiency of the system. Corrosion takes place on the surface of the pipe and can Boreline Instructions For Use & Technical Information -3 Issue Number: 29 Jan 2022

lead to holes. Apart from causing a loss of efficiency through leakage, the water emanating from these holes can damage the casing of the borehole. Corrosion also occurs on the threaded joints of screwed pipe. The threads can corrode to such a degree that the rising main can break off at these points and the rising main, complete with pump and cable, can be lost down the borehole. Not only is this a loss of the pumping equipment but if the riser and pump cannot be recovered, the borehole can be rendered unusable. Corroded threads and bolts on flanges are extremely difficult to remove and can require flame cutting for removal from the borehole. It is this time consuming exercise that causes borehole system users to be reluctant to carry out preventative maintenance on the borehole. If the correct equipment is not available this can be a very costly exercise especially in remote areas. Scale or encrustation often forms on the inside of the steel pipes and reduces the effective bore of the pipe. Additionally, the scaling has a higher coefficient of friction to that of new steel and both of these factors cause a substantial increase in the friction through the pipeline. This increase in friction causes various problems: 1. Reduces flow 2. Prevents the pump from operating at its best efficiency 3. If severe, can cause over heating of the pump motor because of reduced cooling. 4. Reduces the efficiency of the system increasing lifetime costs 5. Substantially increases pump running costs Preventative maintenance is seldom carried out on rising mains and their borehole pumps due to the costs of removal. All too often borehole pumps are run to destruction before replacing but little consideration is given to the rising main on which the pump is suspended. Borehole pumps can outlast the life of a steel rising main. As systems deteriorate they cost more to run, in addition to this, complete operational failure can result in long down time and possible borehole loss. Due to the flexible nature of the Boreline scaling does not build up internally and its efficiency is maintained throughout its life. Boreline is quick and easy to install thus reducing installation costs and allowing more frequent pump maintenance. The efficiency of the entire system is, thereby, retained and downtime kept to a minimum. System Efficiency In recent years the “life costs” of pumping systems have become of prime concern to design engineers and end users. A borehole must be designed to achieve maximum efficiency in both the short and long term – costs to be considered include: 1. 2. 3. 4. 5. Initial capital costs Amortisation of investment Power consumption Supervision and maintenance Cost of down time and standby equipment. A poorly designed borehole or pumping system can result in unacceptably high operational costs. Great care must to be taken when considering the design of the borehole and when selecting a rising main and pump. A pump should always run close to its best efficiency point but if a steel rising main is used and is not regularly maintained, increased friction due to scale will cause the pump to operate out of its design parameters causing numerous problems. Investment in an efficient system will reduce operational and maintenance costs. Boreline Instructions For Use & Technical Information -4 Issue Number: 29 Jan 2022

As an example, a 4” Boreline rising main set at one hundred metres depth, with a flow of 54 m³/hr, has a friction loss of approximately 1.5 metres while an encrusted steel pipe can have a friction loss of 9 metres. This can have severe consequences on the system, due to reduced supply rates, and equates to an additional cost of approximately R 4 600 per year in energy costs alone. These costs cannot be ignored. An added benefit of Boreline is that it expands slightly under pressure providing excellent flow characteristics throughout its life. Description Boreline has been specifically designed to replace rigid risers. Because of its design the use of Boreline results in major savings in time and labour. A pump and column can be installed and retrieved in a fraction of the time required for the rigid riser. In the long term, Boreline is immune from corrosion or internal scaling resulting in further savings. Boreline is a flexible rising main constructed using a combination of the latest high tenacity yarns and thermoplastic materials available in diameters ranging from 1” to 8”. Quality assurance and control are integral to all design and manufacturing procedures through the applications of the International Standards Organisation ISO 9001:2015. Boreline incorporates a cable support rib running the entire length of the hose which allows the electrical cable to be attached to the hose with re-useable cable straps. This cable support rib, which is applied during manufacture, forms an integral part of the hose and has connection points at 1m intervals. Boreline is suitable for operation to depths of 200m Boreline couplings are available in 316 Stainless Steel or Aluminium Bronze (Additionally in Glass Reinforced Nylon for 1” - 4” sizes). The coupling is made up of a body and two sets of fastening clamps. Product Approval Boreline has been tested in accordance with the methods specified in BS 6920: Part 2: 2014. “Suitability of non-metallic products for use in contact with water intended for human consumption with regard to their effect on the quality of the water: Methods of test” and the requirements of the Water Regulations Advisory Scheme ‘WRAS Materials Guidance, Version 4.4 dated 21 November 2016’.The latest test done September 2021. Boreline also has NSF / ANSI 61 Drinking Water approval (http://info.nsf.org/Certified/PwsComponents/index.asp?standard=061) Boreline is approved for use in potable water applications by The Australian Water Quality Centre (Date tested 13.03.98). Hose Manufacturers satisfies the requirements of EN ISO 9001 : 2015 Quality System assessed by TÜV NORD CERT procedures - REGISTRATION No. 44 100 161428 Boreline Instructions For Use & Technical Information -5 Issue Number: 29 Jan 2022

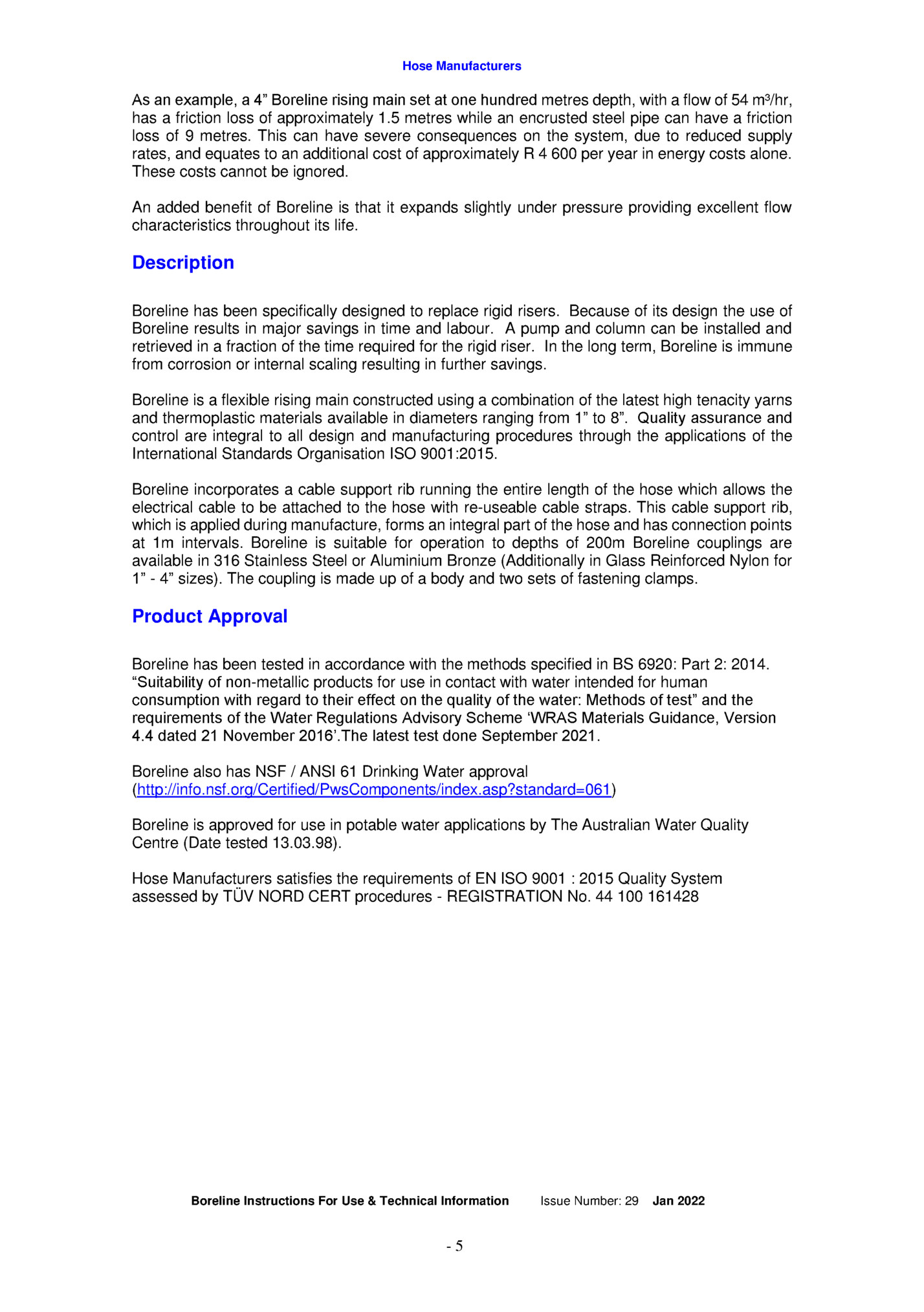

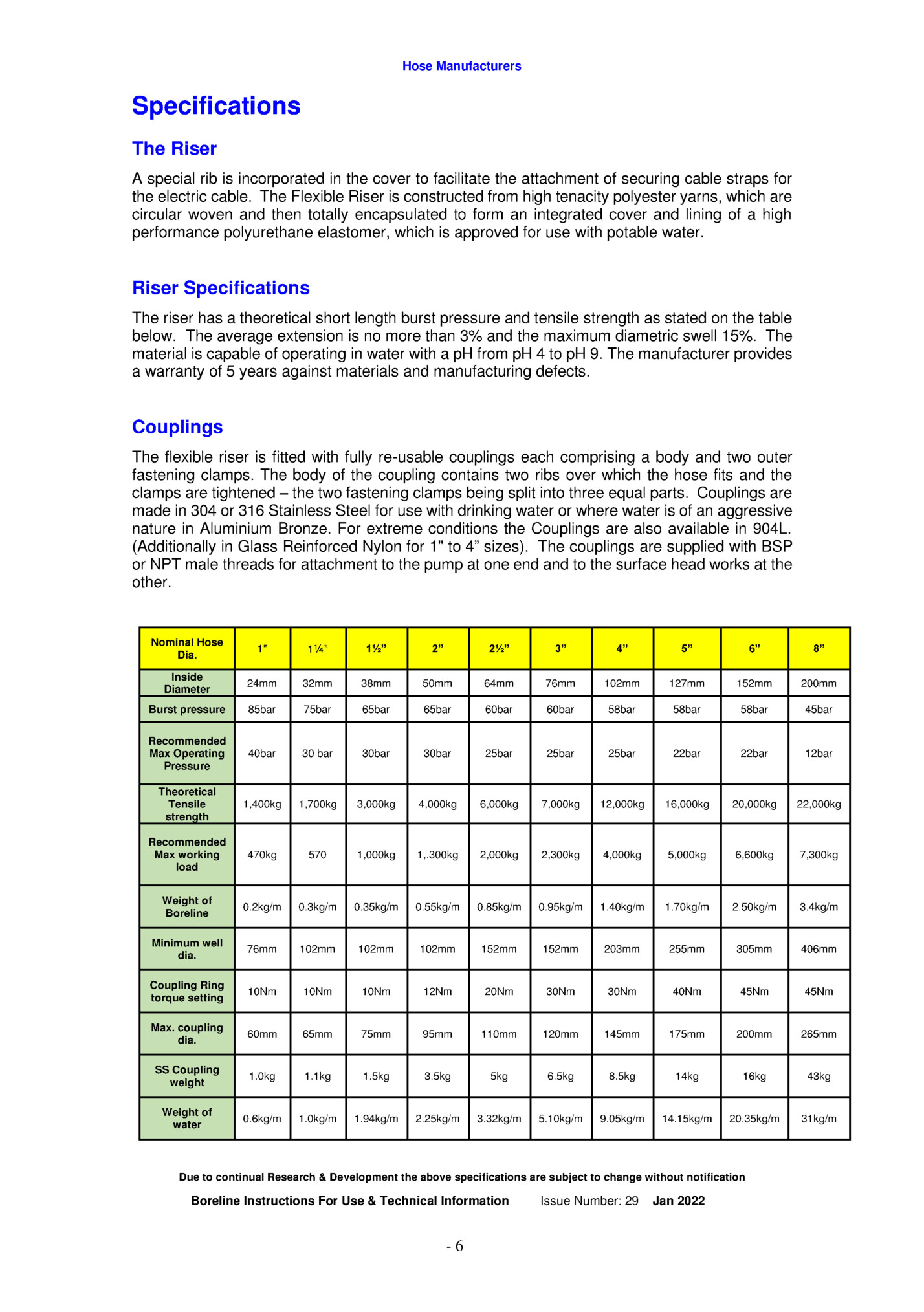

Specifications The Riser A special rib is incorporated in the cover to facilitate the attachment of securing cable straps for the electric cable. The Flexible Riser is constructed from high tenacity polyester yarns, which are circular woven and then totally encapsulated to form an integrated cover and lining of a high performance polyurethane elastomer, which is approved for use with potable water. Riser Specifications The riser has a theoretical short length burst pressure and tensile strength as stated on the table below. The average extension is no more than 3% and the maximum diametric swell 15%. The material is capable of operating in water with a pH from pH 4 to pH 9. The manufacturer provides a warranty of 5 years against materials and manufacturing defects. Couplings The flexible riser is fitted with fully re-usable couplings each comprising a body and two outer fastening clamps. The body of the coupling contains two ribs over which the hose fits and the clamps are tightened – the two fastening clamps being split into three equal parts. Couplings are made in 304 or 316 Stainless Steel for use with drinking water or where water is of an aggressive nature in Aluminium Bronze. For extreme conditions the Couplings are also available in 904L. (Additionally in Glass Reinforced Nylon for 1" to 4” sizes). The couplings are supplied with BSP or NPT male threads for attachment to the pump at one end and to the surface head works at the other. Nominal Hose Dia. 1" 1¼” 1½” 2” 2½” 3” 4” 5” 6" 8” Inside Diameter 24mm 32mm 38mm 50mm 64mm 76mm 102mm 127mm 152mm 200mm Burst pressure 85bar 75bar 65bar 65bar 60bar 60bar 58bar 58bar 58bar 45bar Recommended Max Operating Pressure 40bar 30 bar 30bar 30bar 25bar 25bar 25bar 22bar 22bar 12bar Theoretical Tensile strength 1,400kg 1,700kg 3,000kg 4,000kg 6,000kg 7,000kg 12,000kg 16,000kg 20,000kg 22,000kg Recommended Max working load 470kg 570 1,000kg 1,.300kg 2,000kg 2,300kg 4,000kg 5,000kg 6,600kg 7,300kg Weight of Boreline 0.2kg/m 0.3kg/m 0.35kg/m 0.55kg/m 0.85kg/m 0.95kg/m 1.40kg/m 1.70kg/m 2.50kg/m 3.4kg/m Minimum well dia. 76mm 102mm 102mm 102mm 152mm 152mm 203mm 255mm 305mm 406mm Coupling Ring torque setting 10Nm 10Nm 10Nm 12Nm 20Nm 30Nm 30Nm 40Nm 45Nm 45Nm Max. coupling dia. 60mm 65mm 75mm 95mm 110mm 120mm 145mm 175mm 200mm 265mm SS Coupling weight 1.0kg 1.1kg 1.5kg 3.5kg 5kg 6.5kg 8.5kg 14kg 16kg 43kg Weight of water 0.6kg/m 1.0kg/m 1.94kg/m 2.25kg/m 3.32kg/m 5.10kg/m 9.05kg/m 14.15kg/m 20.35kg/m 31kg/m Due to continual Research & Development the above specifications are subject to change without notification Boreline Instructions For Use & Technical Information -6 Issue Number: 29 Jan 2022

3:1 safety factor applied Benefits of BORELINE ⚫ Available in continuous lengths of up to Superior flow rates ⚫ 300m up to 2”, 200m up to 6”, 8” up to 120m ⚫ Water Research Advisory Council approved BS6920 accredited ⚫ ⚫ NSF / ANSI 61 Drinking Water approved Long life expectancy ⚫ ⚫ Advantageous in restricted working area Potable water approved ⚫ ⚫ Quick and easy to install and retrieve Light weight and rolls flat ⚫ ⚫ Not subject to microbiological attack Less manpower required ⚫ ⚫ Easy to store, handle and transport Tremendous Tensile Strength ⚫ ⚫ Corrosion free and does not scale Superb hydraulic performance ⚫ Applications Boreline has been used in a variety of new and replacement applications. These include the pumping of potable or mineral enriched ground water, regular and emergency dewatering of mines and quarries, ground water control on landfill and building sites and to create salt water barriers for the prevention of saline intrusion into potable ground water. Storage and Handling Boreline is available in continuous lengths of up to 300m – it is normally supplied crated but any odd or unused lengths should be coiled loosely and covered for protection. It is recommended to keep Boreline out of direct sunlight if it’s to be stored for a prolonged period. Because Boreline is lightweight and can be rolled up flat, an ordinary van or pick-up truck can be used to transport it to site, instead of the cumbersome vehicle necessary for rigid pipes. Disposal Boreline will normally be supplied cut to exact length to suit the borehole but occasionally an adjustment may be necessary on site and a length of hose found surplus to requirements. This should be disposed of properly in accordance with local / national industrial waste disposal regulations. Safety Boreline is light in comparison to steel rising main and therefore presents a lesser hazard to personnel when handling. Because Boreline is supplied in continuous lengths care must be taken to ensure that it is either laid out neatly on site or coiled on a drum ( if space is limited ) whenever it is being installed or retrieved. An untidy workplace is a dangerous workplace. Installation instructions must be followed. Boreline must be installed by competent personnel. Care must be taken to ensure that the correct tools are available for the installation. Boreline Instructions For Use & Technical Information -7 Issue Number: 29 Jan 2022

Hazards Boreline presents no chemical or biological hazards in normal usage, nor during installation or retrieval. If Boreline is involved in a fire, during storage or transportation, toxic & irritating gasses may be produced – if inhaled, medical advice should be obtained immediately. Molten material can cause severe burns – no attempt should be made to remove any such contamination from the skin but should be flushed with copious amounts of cold water and medical assistance sought without delay. Boreline Instructions For Use & Technical Information -8 Issue Number: 29 Jan 2022

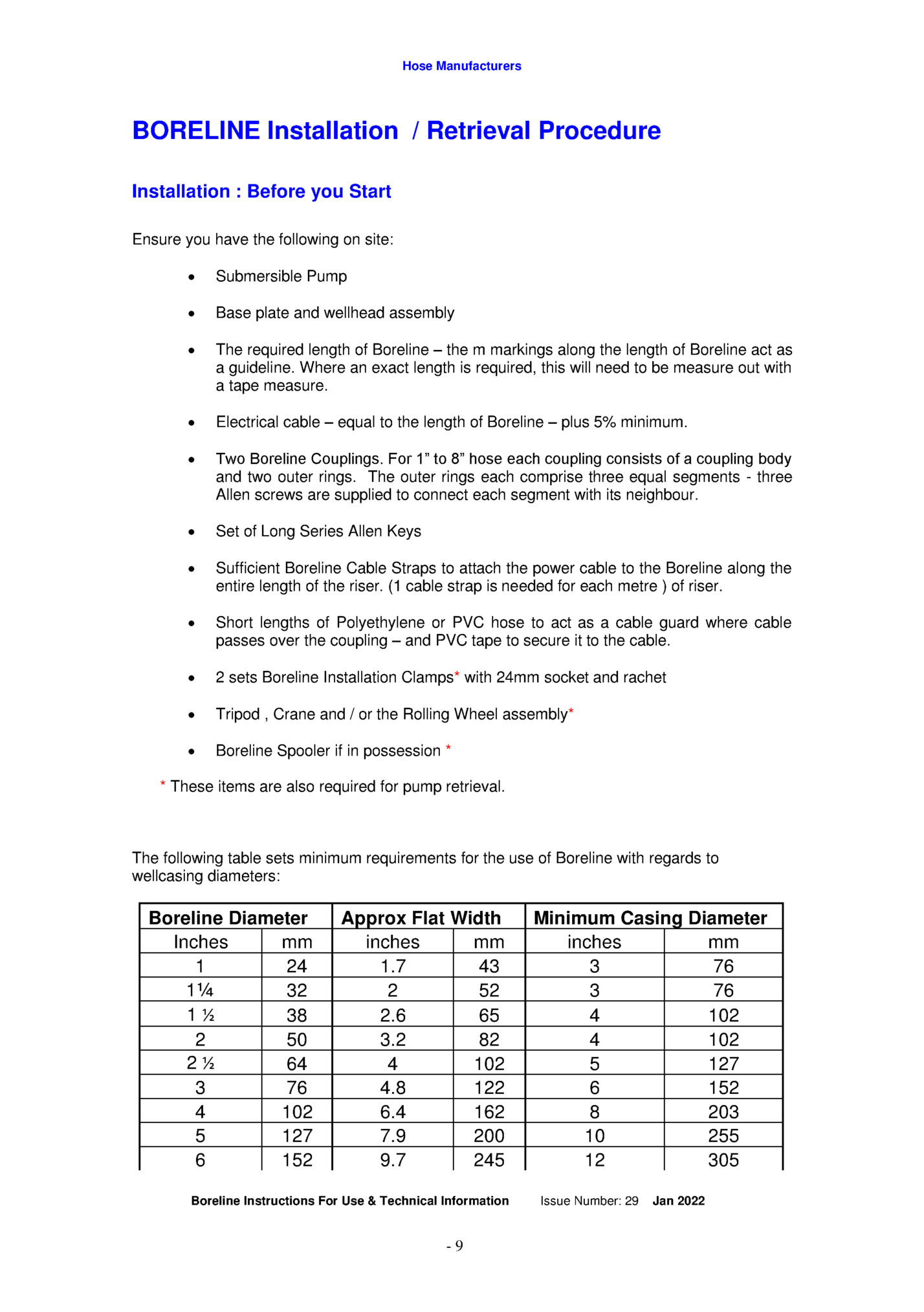

BORELINE Installation / Retrieval Procedure Installation : Before you Start Ensure you have the following on site: • Submersible Pump • Base plate and wellhead assembly • The required length of Boreline – the m markings along the length of Boreline act as a guideline. Where an exact length is required, this will need to be measure out with a tape measure. • Electrical cable – equal to the length of Boreline – plus 5% minimum. • Two Boreline Couplings. For 1” to 8” hose each coupling consists of a coupling body and two outer rings. The outer rings each comprise three equal segments - three Allen screws are supplied to connect each segment with its neighbour. • Set of Long Series Allen Keys • Sufficient Boreline Cable Straps to attach the power cable to the Boreline along the entire length of the riser. (1 cable strap is needed for each metre ) of riser. • Short lengths of Polyethylene or PVC hose to act as a cable guard where cable passes over the coupling – and PVC tape to secure it to the cable. • 2 sets Boreline Installation Clamps* with 24mm socket and rachet • Tripod , Crane and / or the Rolling Wheel assembly* • Boreline Spooler if in possession * * These items are also required for pump retrieval. The following table sets minimum requirements for the use of Boreline with regards to wellcasing diameters: Boreline Diameter Inches mm 1 24 1¼ 32 1½ 38 2 50 2½ 64 3 76 4 102 5 127 6 152 Approx Flat Width inches mm 1.7 43 2 52 2.6 65 3.2 82 4 102 4.8 122 6.4 162 7.9 200 9.7 245 Boreline Instructions For Use & Technical Information -9 Minimum Casing Diameter inches mm 3 76 3 76 4 102 4 102 5 127 6 152 8 203 10 255 12 305 Issue Number: 29 Jan 2022

Fleepit Digital © 2021