Content 1. àÅí ééÑ IBT ltd. 4 2. è‰ÒÚ‡‚flÌ ̇ ÚÂıÌÓÎÓ„ËflÚ‡ Presentation of the technology 6 3. ëÚÓËÚÂÎÒÚ‚Ó ÔÓ ÚÂıÌÓÎÓ„ËflÚ‡ Building by this technology 8 4. è‰ËÏÒÚ‚‡ ̇ ÚÂıÌÓÎÓ„ËflÚ‡ Ädvantages of the technology 14 3

ëÚÓËÚÂÎ̇ ÒËÒÚÂχ “ àÅí“ INTRODUCTIONOFTHE“IBT”TECNOLOGY åËÒËflÚ‡ ̇ “àÅí” e ‰‡ ‰ÓÒÚ‡‚Ë Ì‡ ÍÎËÂÌÚ‡ ËÌÚ„ˇ̇ ÍÓÌÒÚÛÍÚ˂̇ ÚÂıÌÓÎÓ„Ëfl, ͇ÚÓ Ô‰ÒÚ‡‚fl ‰ËÌ ÓÚ Ì‡È-ÛÒ˙‚˙¯ÂÌÒÚ‚‡ÌËÚ ÓÚ„Ó‚ÓË Ì‡ ÚÂıÌÓÎÓ„ËflÚ‡ ÔÓ ÓÚÌÓ¯ÂÌË ̇ ‚ÂÏÂÚÓ Ë „ÎÓ·‡ÎÌËfl ËÍÓÌÓÏ˘ÂÒÍË ·‡Î‡ÌÒ ‚˙‚ ‚˙Á͇ Ò Ô·ÌˇÌÂÚÓ Ì‡ ËÌÚÂÌÁË‚ÌÓ ËÁ„‡Ê‰‡Ì ̇ Ò„‡‰Ë ‚ Ò‚ÂÚÓ‚ÂÌ Ï‡˘‡·, ÍÓÂÚÓ ÒÚ‡‚‡ flÒÌÓ ÓÚ ÛÒÔ¯ÌÓÚÓ ÏÛ ‡ÁÔÓÒÚ‡ÌÂÌË ̇ ‚Ò˘ÍË ÍÓÌÚËÌÂÌÚË. “ I B T ” technology represents today one of the most advanced and privilege technological answers, in meansof time and global economic balance, to the plans of an intensive production of buildings at a global level, how demonstrated in the success obtained in its actual diffusion in all continents. éÒÌӂ̇ڇ ˉÂfl Ò Ò˙ÒÚÓË ‚˙‚ ‚˙ÁÏÓÊÌÓÒÚÚ‡ ‰‡ Ò ÍÓÏ·ËÌË‡Ú ËÁÍβ˜ËÚÂÎÌÓ ·Î‡„ÓÔËflÚÌÓ ÍÓÌÒÚÛÍÚË‚ÌËÚÂ Ë ÚÓÔÎÓËÁÓ·ˆËÓÌÌË ËÁËÒÍ‚‡ÌËfl ̇ ÍÓÌÒÚÛ͈ËËÚ ËÁ„‡‰ÂÌË ÔÓ ÚÂıÌÓÎÓ„ËflÚ‡ “àÅí” Ë Ú‡‰ËˆËÓÌÌËÚ ‰Ó‚˙¯ËÚÂÎÌË ÒÚÓËÚÂÎÌË ÏÂÚÓ‰Ë. The basic idea consists in the possibility to combine, in conditions of remarkable advantage the structure and thermal insulation requirements of the structures made of reinforced concrete together with the traditional building methods. í‡ÁË ˆÂÎ Â ÔÓÒÚ˄̇ڇ, ˜ÂÁ ËÁ‡·ÓÚ‚‡Ì ‚ Ë̉ÛÒÚˇÎÌË ÛÒÎÓ‚Ëfl ̇ Ò„ÎÓ·flÂÏË ÓÎÂÍÓÚÂÌË (ÏÓ‰ÛÎÌË) Ô‡ÌÂÎË ËÁ‡·ÓÚÂÌË ÓÚ EPS-F Ò ÔÓ‰ıÓ‰fl˘‡ ÔÎ˙ÚÌÓÒÚ Ë „‡Î‚‡ÌËÁˇ̇ ÂÎÂÍÚÓÁ‡‚‡Â̇ ÒÚÓχÌÂ̇ ÏÂʇ. The purpose has been validly reached with the development of a prefabricated light panel (modular) made of an expanded polystyrene plate of suitable density, between two mesh sheets of galvanised and welded wire. “IBT” s an innovative earthquake-resistant and insulating building system enabling the construction of earthquake-resistant buildings from 1 up to 20 storeys as well as architectural structures from the simplest to the most complex. ëΉ ÏÓÌÚˇÌÂÚÓ, ÒΉ‚‡ ÔÓ·„‡ÌÂÚÓ Ì‡ ·ÂÚÓÌ (CLS), ÍÓÂÚÓ Â ËÁÍβ˜ËÚÂÎÌÓ ÎÂÒ̇ Ôӈ‰ۇ. After the mounting, the panel is completed with the application of the concrete (CLS), by easy procedures. èÓ ÚÓÁË Ì‡˜ËÌ ÚÂıÌÓÎÓ„ËflÚ‡ “ àÅí “ Ô‰ÒÚ‡‚fl Ë̉ÛÒÚˇÎÂÌ ÔÓ‰ÛÍÚ Ò ‡ÁÌÓÓ·‡ÁÌË ÍÓÌÒÚÛÍÚË‚ÌË ÂÎÂÏÂÌÚË: The “ I B T ” technology allows, in this way, to produce a wide range of constructive elements: l l l l l l 4 çÓÒÂ˘Ë ÒÚÂÌË Ò˙ÒÚ‡‚ÂÌË ÓÚ ‰‚ÛÒÎÓÈÌË ËÎË Â‰ÌÓÒÎÓÈÌË Ô‡ÌÂÎË ÒÔÓ‰ ÍÓÌÒÚÛÍÚË‚ÌËÚ ËÁËÒÍ‚‡ÌËfl . 脇‰ÌË, ‚˙̯ÌË Ë ‚˙Ú¯ÌË ÒÚÂÌË ,ÓÚ Â‰ÌÓÒÎÓÈÌË Ô‡ÌÂÎË Ò ÔÓ‰ıÓ‰fl˘Ë ‡ÁÏÂË. èÔÎÓÒÍË Ë Ì‡ÍÎÓÌÂÌË ÔÓÍË‚Ë Ò ‚˙ÁÏÓÊÌÓÒÚ Á‡ Ò‚ÂÚÎË ÓÚ‚ÓË. ëÚ˙ηˢ‡ åÂÊ‰Û ÒÚ˙ηˢÌË ÔÎÓ˘‡‰ÍË l l l Bearing walls, made of panels type “double”, or panels type “single” in specif ic situations with the condition of structural constraint . Partition and external luting walls, by using the “single panel” appropriately dimensioned. Trampling, f lat and inclined roof ing f loors with the “roof ing panel”. Stairs. 5

“àÅí” Â ËÌÓ‚‡ˆËÓÌ̇, ËÁÓ·ˆËÓÌ̇ Ë ‡ÌÚËÒÂËÁÏ˘̇ ÍÓÌÒÚÛÍÚ˂̇ ÒÚÓËÚÂÎ̇ ÒËÒÚÂχ,·‡Áˇ̇ ̇ ÏÓ‰ÛÎÌË, ÚÂÏÓËÁÓ·ˆËÓÌÌË Ô‡ÌÂÎË ÔÓËÁ‚‰ÂÌË ÔÓ Ë̉ÛÒÚˇÎÂÌ Ô˙Ú, ‰‡‚‡˘Ë ‚˙ÁÏÓÊÌÓÒÚ ‰‡ Ò ËÁÔ˙ÎÌfl‚‡Ú ÂÙË͇ÒÌÓ ÌÂÓ·ıÓ‰ËÏËÚ ÒÚÛÍÚÛÌË ÙÛÌ͈ËË Ì‡ ÒÚÓÂÊËÚÂ, „‡‡ÌÚˇ˘Ë ‚ËÒÓ͇ ÚÓÔÎÓ , ÚÂÏÓËÁÓ·ˆËfl Ë „ÓÎflχ ÛÒÚÓȘ˂ÓÒÚ Ì‡ Á‡ÏÂÚÂÒÂÌËfl Ë Ó„˙Ì.“àÅí” Ô‚˙ÁıÓʉ‡ ÔÓ ·˙ÁË̇ ̇ ËÁÔ˙ÎÌÂÌËÂÚÓ Ë Ì‡‰ÂʉÌÓÒÚ ‚Ò˘ÍË ÓÒڇ̇ÎË ÍÓÌÒÚÛÍÚË‚ÌË ÒËÒÚÂÏË, Ú‡‰ËˆËÓÌÌË ËÎË Ò „ÓÚÓ‚Ë ÂÎÂÏÂÌÚË, ͇ÚÓ ‰ÂÏÓÌÒÚˇ Ë Á̇˜ËÚÂÎÌË Ô‰ËÏÒÚ‚‡. “àÅí” Â Ò˙‚˙¯Â̇ ÒËÒÚÂχ, Ò ÍÓflÚÓ Â ‚˙ÁÏÓÊÌÓ ‰‡ Ò ‡ÎËÁË‡Ú ÓÚ Ì‡ÈÔÓÒÚËÚ ‰Ó ̇È-ÒÎÓÊÌËÚ ‡ıËÚÂÍÚÛÌË ÔÓÂÍÚË, ÓÚ Ì‡È-ÌËÒ͇ ÂÚ‡ÊÌÓÒÚ ‰Ó ‚ËÒÓ͇ ÂÚ‡ÊÌÓÒÚ Ò Ì‡‰ 20 Âڇʇ ‚ËÒÓ˜Ë̇, ·ÂÁ Ò˙ÏÌÂÌË ‚ ͇˜ÂÒÚ‚‡Ú‡ È Ì‡ ‡ÌÚËÒÂËÁÏ˘ÌÓÒÚ. ëÚÓËÚÂÎ̇ڇ ÒËÒÚÂχ “àÅí” Â ·‡Áˇ̇ ̇ ÏÓ‰ÛÎÌË ÂÎÂÏÂÌÚË Ò˙ÒÚ‡‚ÂÌË ÓÚ ÓÙÓÏÂÌË EPS –F Ô‡ÌÂÎË ÍÓËÚÓ Ò‡ ÔÓÒÚ‡‚ÂÌË ÏÂÊ‰Û ‰‚ „‡Î‚‡ÌËÁˇÌË ÂÎÂÍÚÓÁ‡‚‡ÂÌË ÏÂÊË.ÇÂÚË͇ÎÌËÚ ÚÂÎÓ‚Â Ò‡ ÔÓÒÚ‡‚ÂÌË ÔÓ ˆÂÎËÚ ÔÓÎËÒÚËÂÌÌË ‘‚˙ÎÌË’ Ò˙Á‰‡‚‡ÈÍË ÔÓ‰ÒËÎÂÌË ÏËÍÓ ÓÔÓË, ÍÓ„‡ÚÓ Ô‡Ì·  ÔÓÍËÚ Ò ·ÂÚÓÌ.ÖÎÂÍÚÓÁ‡‚‡ÂÌËÚ ÏÂÊË Ò‡ Ò‚˙Á‡ÌË Â‰Ì‡ Í˙Ï ‰Û„‡ ˜ÂÁ ÓÚÓ„Ó̇ÎÌÓ ÂÎÂÍÚÓÁ‡‚‡ÂÌË ÏÂÚ‡ÎÌË ‰ËÒڇ̈ËÓÌÂË.íÓ‚‡  „‡‡ÌˆËfl Á‡ Á‰‡‚Ë̇ ÔË ËÁÎË‚‡ÌÂÚÓ Ë ‚˷ˇÌÂÚÓ Ì‡ ·ÂÚÓ̇ ‚ ÍÛıËÌËÚ ̇ Ô‡ÌÂÎËÚÂ.ɯ͇ ÔË ‚˙ÁÍËÚ  Ô‰ÓÚ‚‡ÚÂ̇, ˜ÂÁ ÂÎÂÍÚÓÁ‡‚fl‚‡Ì ‚ Ë̉ÛÒÚˇÎÌË ÛÒÎÓ‚Ëfl , ıÓ‰‡ ̇ ‚Ò˘ÍË Ì‡‰Î˙ÊÌË Ë Ì‡Ô˜ÌË ‚˙ÁÍË Â Ô‰ÓÚ‚‡ÚÂÌ ˜ÂÁ ÌÂ-‰ÂÙÓÏˇ˘ËÚ Ò EPS -F Ò ԇÌÂÎË. Çˉӂ ԇÌÂÎË l l l l 6 Ö‰ÂÌ˘ÂÌ Ô‡ÌÂÎ- ËÁÔÓÎÁ‚‡ Ò ͇ÚÓ ÌÓÒ¢‡ ÍÓÌÒÚÛ͈Ëfl Á‡ Ò„‡‰Ë ‰Ó 4 Âڇʇ Ò ÔÓ·„‡Ì ̇ ÒÚÛÍ ÚÛ̇ Á‡Ï‡Á͇ Ë Ì‡ ‰‚ÂÚ ÒÚ‡ÌË,Á‡ Ô„‡‰ÌË ÒÚÂÌË, ‡Á‰ÂÎËÚÂÎÌË ÒÚÂÌË ‚ ÌÓ‚Ë Ò„‡‰Ë ËÎË Á‡ ÂÏÓÌÚ Ì‡ ÒÚ‡Ë Ò„‡‰Ë Á‡ ‡Á‰ÂÎflÌ ̇ ÔÓÏ¢ÂÌËfl ‚ Ë̉ÛÒÚˇÎÌË Ú˙„Ó‚ÒÍË Ò„‡‰Ë. Ñ‚ÓÂÌ Ô‡ÌÂÎ- Ò˙ÒÚ‡‚ÂÌ Â ÓÚ ‰‚‡ ·‡ÁÓ‚Ë Ô‡Ì·, ÔÓÙËΡÌË Ë Ò˙‰ËÌÂÌË ÔÓÏÂÊ‰Û ÒË Ò ÏÂڇΠÌË ‰ËÒڇ̈ËÓÌÂË, ÍÓËÚÓ Ò˙Á‰‡‚‡Ú ‚˙Ú¯ÌÓ ÔÓÒÚ‡ÌÒÚ‚Ó Á‡ Á‡Ô˙΂‡ÌÂ Ò ·ÂÚÓÌ Ò˙Ò Ò˙ÓÚ ‚ÂÚÌÓÚÓ Í‡˜ÂÒÚ‚Ó Ë ÂÁËÒÚÂÌÚÌÓÒÚ. Ñ·ÂÎË̇ڇ ̇ ÒÎÓfl ÓÚ ·ÂÚÓÌ ‚˙‚ ‚˙Ú¯ÌÓÒÚÚ‡ ̇ “‰‚ÓÈÌËfl Ô‡ÌÂΔ, ͇ÍÚÓ Ë Í‡˜ÂÒÚ‚‡Ú‡ ̇ ËÁÔÓÎÁ‚‡ÌËfl ·ÂÚÓÌ Ò ÓÔ‰ÂÎflÚ ‚ Á‡‚ËÒËÏÓÒÚ ÓÚ ÒÚÛÍÚÛÌËÚ ËÁËÒÍ‚‡ÌËfl. èÓÍË‚ÂÌ / èÓ‰Ó‚ Ô‡ÌÂÎ - è‡Ì·  Ò˙Á‰‡‰ÂÌ Á‡ ‡ÎËÁˇÌ ̇ ÏÂʉÛÂÚ‡ÊÌË Ë ÔÓÍË‚ÌË ÔÎÓ˜Ë Ò „ÓÎÂÏË ÓÚ‚ÓË, ‚ ÍÓËÚÓ Ò ‚͇‚‡Ú ÒÚÓχÌÂÌËÚ „Â‰Ë ‚ ÒÔˆˇÎÌÓ Ô‰̇Á̇˜ÂÌË ÔÓÒÚ‡Ì ÒÚ‚‡ Ë Ò Á‡Ô˙΂‡Ú Ò ·ÂÚÓÌ. ëÚ˙ηˢÂÌ Ô‡ÌÂÎ- Ò˙ÒÚÓË Ò ÓÚ ÔÓÎËÒÚËÂÌÓ‚ ·ÎÓÍ ÔÓÙËÎË‡Ì ÒÔÓ‰ ÔÓÂÍÚÌËÚ ËÁËÒÍ‚‡ÌËfl, ÔÓÍËÚ Ò 2 ÏÂÚ‡ÎÌË ÏÂÊË ‡ÒÂÏ·ÎË‡Ì ˜ÂÁ ÂÎÂÍÚÓÁ‡‚‡Â̇ ÒÚÓχÌÂ̇ ÚÂÎ. íÓÁË Ô‡ÌÂÎ, Ò˙ÓÚ‚ÂÚÌÓ ‡ÏË‡Ì Ë Á‡Ô˙ÎÌÂÌ Ò ·ÂÚÓÌ ‚ ÒÔˆˇÎÌÓ ÓÔ‰ÂÎÂÌËÚ Á‡ ÚÓ‚‡ ÔÓÒÚ‡ÌÒÚ‚‡, Ò ËÁÔÓÎÁ‚‡ Á‡ ËÁ„‡Ê‰‡Ì ̇ ÒÚ˙ηˢ‡ Ë ‡ÏÔË Ò˙Ò Ò‚Ó·Ó‰ÂÌ ÓÚ‚Ó ÓÚ 6 ÏÂÚ‡. è‡ÌÂÎ˙Ú Á‡ ÒÚ˙Î·Ë ˘‡Ú‡ Ò ı‡‡ÍÚÂËÁˇ Ò ÎÂÒÌÓ Ë ·˙ÁÓ ÔÓÒÚ‡‚flÌ ̇ ÏflÒÚÓ. The IBT construction system is based on modular elements made of shaped polystyrene panels that are obtained between two sheets of galvanized welded meshes. The vertical mesh wires are set along the polystyrene ‘waves’ thus creating reinforced concrete micro pillars once the panel is coated with concrete (this technique has been successfully to reinforce historic or artistic buildings). The above wires are bounded to each other by the mesh ‘horizontal wires and joined orthogonally by the links which keep the two meshes together. Joint twisting is prevented by welding; in other words, as these joints are all welded, all transversal and longitudinal motion is prevented resulting in absolute in deformable panels. Types of panels: l l l l Single panel - as a load-bearing structure, up to 4 storey buildings, with structural plastering on the two surfaces; - for partition walls and curtain walls, in buildings either new or to be restored; - for curtain walls and partition walls in large industrial and commercial buildings; - as a disposable insulating formwork for roofs and f loors of small-sized spans, with or without precastribs. Double panel it consists of two basic panels, suitably shaped and joined one another by double horizontal connectors, so as to form an air space to be f illed with concrete, having suitable characteristics and strength. The thickness of the concrete casting inside the double panel as wellas the characteristics of the concrete itself will be def ined according to structural requirements. Roof/Floor panel used in the construction of large-sized span f loors by placing integrative steel in the spaces moulded for this purpose (bar joists) and casting concrete. Staircase panel it consists of a foam polystyrene block shaped according to designing requirements, coated with two layers of steel wire mesh assembled with electrowelded wire. This panel, suitably reinforced and f inished with casting on site in the suitable spaces, is used to build f lights of stairs up to a maximum span of 6 m. The stairs panel is characterised by its extremely easy laying along with its special structural resistance and lightness. 7

ÒÚÓËÚÂÎÒÚ‚Ó ÔÓ ÚÂıÌÓÎÓ„ËflÚ‡ 2. ë„ÎÓ·fl‚‡Ì ̇ ‰‚ÓÈÌË Ô‡ÌÂÎË: ·Î‡„Ó‰‡ÂÌË ̇ ÎÂÍÓÚ‡Ú‡ ̇ ‚ÒÂÍË Ô‡ÌÂÎ, ÚÓÈ ÏÓÊ ‰‡ ·˙‰Â Ó·ÒÎÛÊÂÌ ÓÚ Â‰ËÌ ‡·ÓÚÌËÍ Ë ÙËÍÒË‡Ì ˜ÂÁ Ó·ËÍÌÓ‚ÂÌ Ò‚˙Á‚‡˘ ËÌÒÚÛÏÂÌÚ. building by this technology 2. Double panels are assembled: thanks to its lightness every panel can be handled by one workman and the f ixed by means of ‡ simple tying tool. 3.ëΉ ͇ÚÓ ·ø‰Â Á‡‚ø¯Â̇ Ú‡ÁË ÒÚ˙Ô͇, ÍÛıË̇ڇ ÏÓÊ ‰‡ ·˙‰Â Á‡Ô˙ÎÌÂ̇ Ò˙Ò ·ÂÚÓÌ. ëÚÓËÚÂÎÒÚ‚ÓÚÓ ÔÓ ÚÂıÌÓÎÓÚËflÚ‡ “àÅí” Â ÎÂÒÌÓ. è‡ÌÂÎËÚ “àÅí” ÎÂÒÌÓ Ò ÔÂ̇ÒflÚ, Ú‡ÌÒÔÓÚË‡Ú Ë ËÌÒÚ‡ÎË‡Ú ·Î‡„Ó‰‡ÂÌË ̇ ËÁ‚˙̉ÌÓ Ï‡ÎÍÓÚÓ ÒË Ú„ÎÓ, ÍÓÂÚÓ ÔÓÁ‚ÓÎfl‚‡ ËÁÔÓÎÁ‚‡ÌÂÚÓ ËÏ ÔË ‚ÒflÍ‡Í‚Ë ÛÒÎÓ‚Ëfl. å‡ÎÍÓÚÓ Ú„ÎÓ Â Ò˙˜ÂÚ‡ÌÓ Ò „ÓÎflχ Á‰‡‚Ë̇ ‰ÓË Ë ÔÂ‰Ë ÔÓ·„‡ÌÂÚÓ Ì‡ ÒÚÛÍÚÛÌËfl ·ÂÚÓÌ, ÍÓÂÚÓ „‡‡ÌÚˇ ÍÓÏÔ‡ÍÚÌÓÒÚ Ë ËÁÔ˙ÎÌÂÌË ̇ ÛÒÎÓ‚ËflÚ‡ Á‡ ÍÓËÚÓ Ò‡ Ô‰̇Á̇˜ÂÌË Ô‡ÌÂÎËÚÂ. í„ÎÓÚÓ Ì‡ Í‚‡‰‡ÚÂÌ ÏÂÚ˙ ̇ Ô‡ÌÂÎËÚ ÔÂ‰Ë ÔÓ·„‡ÌÂÚÓ Ì‡ ·ÂÚÓ̇ ‚‡Ë‡ ‚ Á‡‚ËÒËÏÓÒÚ ÓÚ ‚ˉ‡ ̇ ԇ̷ ÓÚ 3,5 Í„/Ï2 ‰Ó 5Í„/Ï2 ,ÚÓ‚‡ ÔÓÁ‚ÓÎfl‚‡ ‡·ÓÚÌË͇ Ò‡Ï ‰‡ ÓÔ¡ Ò ÎÂÍÓÚ‡ Ò 4 Ï2 Ô‡ÌÂÎ. çÂÓ·ıÓ‰ËÏÓÒÚÚ‡ ÓÚ ÚÂÊ͇ ÏÂı‡ÌËÁ‡ˆËfl ÓÚÔ‡‰‡. 1. èÓ·„‡Ì ̇ ÓÒÌÓ‚Ë. The “IBT” building system technology is very easy. The different steps are described below. Thanks to their light weight, on the building sites, “IBT” panels can be easily carried by force by one or two workers, even when assembled and when measuring over 4 sq.m. In the following stage, they may be handled and placed by hand by only one worker without the aid of a lifting machine. This makes their installation easier and more rapid in any situation, with no need for skilled labour. Of course, in case skilled workers were employed, there would be a marked increase in productivity. Due to its remarkably light weight“IBT” panels are easy and rapid to carry and handle. “IBT” panels may be placed by hand and are connected one to the other with either a pneumatic gun or ordinary building wire. 3.Once this step is completed, the hollow may be f illed with concrete. 1. Foundation bin 8 9

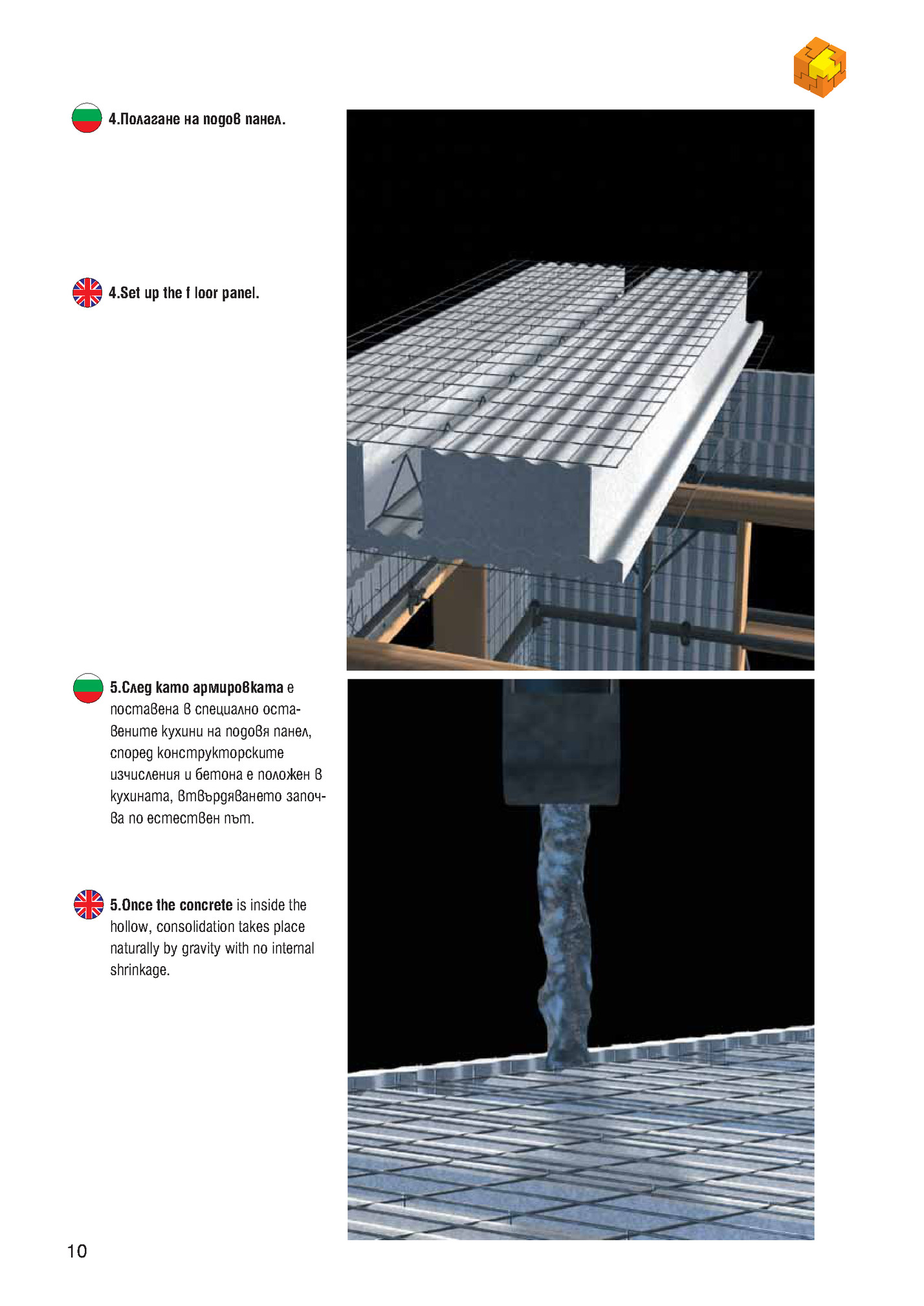

4.Set up the f loor panel. 6.The furrow is carried out with a standard hot air gun. 5.ëΉ ͇ÚÓ ‡ÏËӂ͇ڇ  ÔÓÒÚ‡‚Â̇ ‚ ÒÔˆˇÎÌÓ ÓÒÚ‡‚ÂÌËÚ ÍÛıËÌË Ì‡ ÔÓ‰Ó‚fl Ô‡ÌÂÎ, ÒÔÓ‰ ÍÓÌÒÚÛÍÚÓÒÍËÚ ËÁ˜ËÒÎÂÌËfl Ë ·ÂÚÓ̇  ÔÓÎÓÊÂÌ ‚ ÍÛıË̇ڇ, ‚Ú‚˙‰fl‚‡ÌÂÚÓ Á‡ÔÓ˜‚‡ ÔÓ ÂÒÚÂÒÚ‚ÂÌ Ô˙Ú. 7.í‡Í‡ ‡·ÓÚÌË͇ ÔÂχı‚‡ ÂÎÂÍÚÓÁ‡‚‡Â̇ڇ ÒÚÓχÌÂ̇ ÏÂʇ, ÂÊÂÈÍË ˜‡ÒÚË ÓÚ ÌÂfl Ò ÔÓÏÓ˘˘‡ ̇ ÔÌ‚χÚ˘ÌË ËÎË Òڇ̉‡ÚÌË ÌÓÊˈË. 5.Once the concrete is inside the hollow, consolidation takes place naturally by gravity with no internal shrinkage. 10 6.ä‡Ì‡ÎËÚ Á‡ ÇËä Ë ÂÎÂÍÚ˘ÂÒ͇ڇ ËÌÒڇ·ˆËfl Ò ËÁ‚˙¯‚‡Ú Ò ÔÓÏÓ˘Ú‡ ̇ Òڇ̉‡Ú̇ ÚÓÔ· ‚˙Á‰Û¯Ì‡ Ôۯ͇ (·ÂÌÂ). 7.The workman can now make the chases cutting the electro welded metal mesh with pneumatic end standarts shears. 11

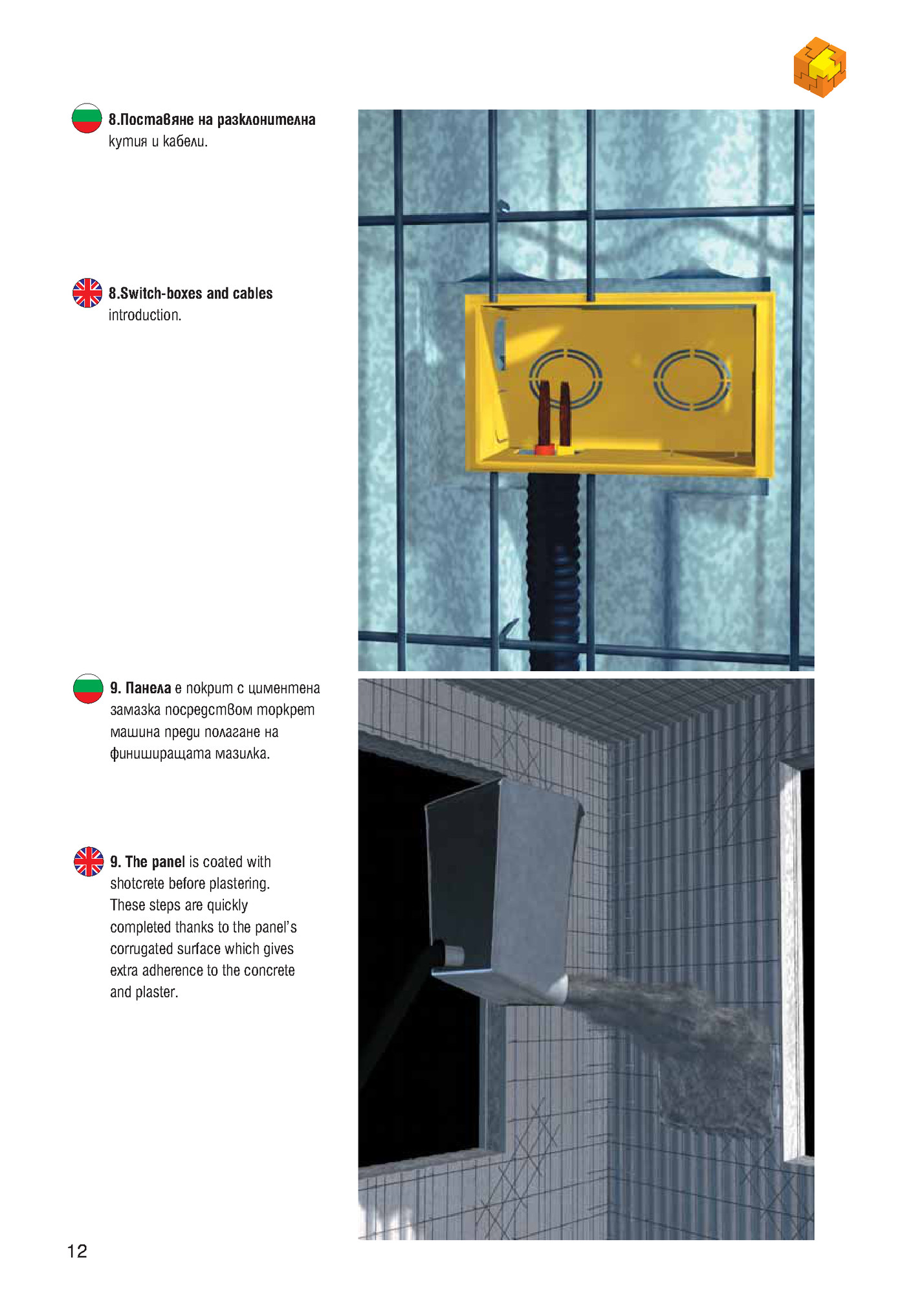

ÍÛÚËfl Ë Í‡·ÂÎË. 8.Switch-boxes and cables introduction. 9. è‡Ì·  ÔÓÍËÚ Ò ˆËÏÂÌÚÂ̇ Á‡Ï‡Á͇ ÔÓÒ‰ÒÚ‚ÓÏ ÚÓÍÂÚ Ï‡¯Ë̇ ÔÂ‰Ë ÔÓ·„‡Ì ̇ ÙËÌ˯ˇ˘‡Ú‡ χÁËÎ͇. 9. The panel is coated with shotcrete before plastering. These steps are quickly completed thanks to the panel’s corrugated surface which gives extra adherence to the concrete and plaster. 12 13

Ô‰ËÏÒÚ‚‡ ̇ ÚÂıÌÓÎÓ„ËflÚ‡ 4. advantages of the technology 䇘ÂÒÚ‚Ó Ì‡ ÒÚÛÍÚÛ‡Ú‡. éÚ΢ÌÓ Ôӂ‰ÂÌË ̇ ÒÚÛÍÚÛ‡Ú‡ ÔË ÒÂËÁÏ˘ÌÓ ‰ÂÈÒÚ‚ËÂ: Ò„‡‰‡ ÔÓÒÚÓÂ̇ ÔÓ ÚÂıÌÓÎÓ„ËflÚ‡ ̇ “”àÅí” ‚Ó‰Ë ‰Ó 20 Ô˙ÚË ÔÓ-χÎÍÓ ‰ÂÙÓχˆËfl ‚ Ò‡‚ÌÂÌËÂ Ò ‰Û„Ë Ú‡‰ËˆËÓÌÌË Ò„‡‰Ë ÔË Ò˙˘ËÚ ÛÒÎÓ‚Ëfl. “”àÅí” Ò˙‚˙¯Â̇ ÒËÒÚÂχ, Ò ÍÓflÚÓ Â ‚˙ÁÏÓÊÌÓ ‰‡ Ò ‡ÎËÁË‡Ú ÓÚ Ì‡È-ÔÓÒÚËÚ ‰Ó ̇È-ÒÎÓÊÌËÚ ‡ıËÚÂÍÚÛÌË ÔÓÂÍÚË, ÓÚ Ì‡È-ÌËÒ͇ ÂÚ‡ÊÌÓÒÚ ‰Ó ‚ËÒÓ͇ ÂÚ‡ÊÌÓÒÚ Ò 20 Âڇʇ ‚ËÒÓ˜Ë̇, ·ÂÁ Ò˙ÏÌÂÌË ‚ ͇˜ÂÒÚ‚‡Ú‡ Ë Ì‡ ‡ÌÚËÒÂËÁÏ˘ÌÓÒÚ. ëËÒÚÂχڇ Ò Ò˙Ô˙ÚÒÚ‚Û‚‡ Ò˙Ò ÒÓÙÚÛ Á‡ ËÁ˜ËÒÎfl‚‡Ì ̇ Ôӂ‰ÂÌËÂÚÓ Ì‡ Ò„‡‰‡Ú‡ ÔË ÒÂËÁÏ˘ÌÓÒÚ . Quality of the structure. Excellent behaviour of the structure under seismic action: a building made by IBT system results 20 times less deformable in relation with other traditional building under the same conditions. The advantages offered by IBT construction system are considerable; They include soundproof ing, heat insulation, f ire resistance, crash and earthquake resistance. 14 15

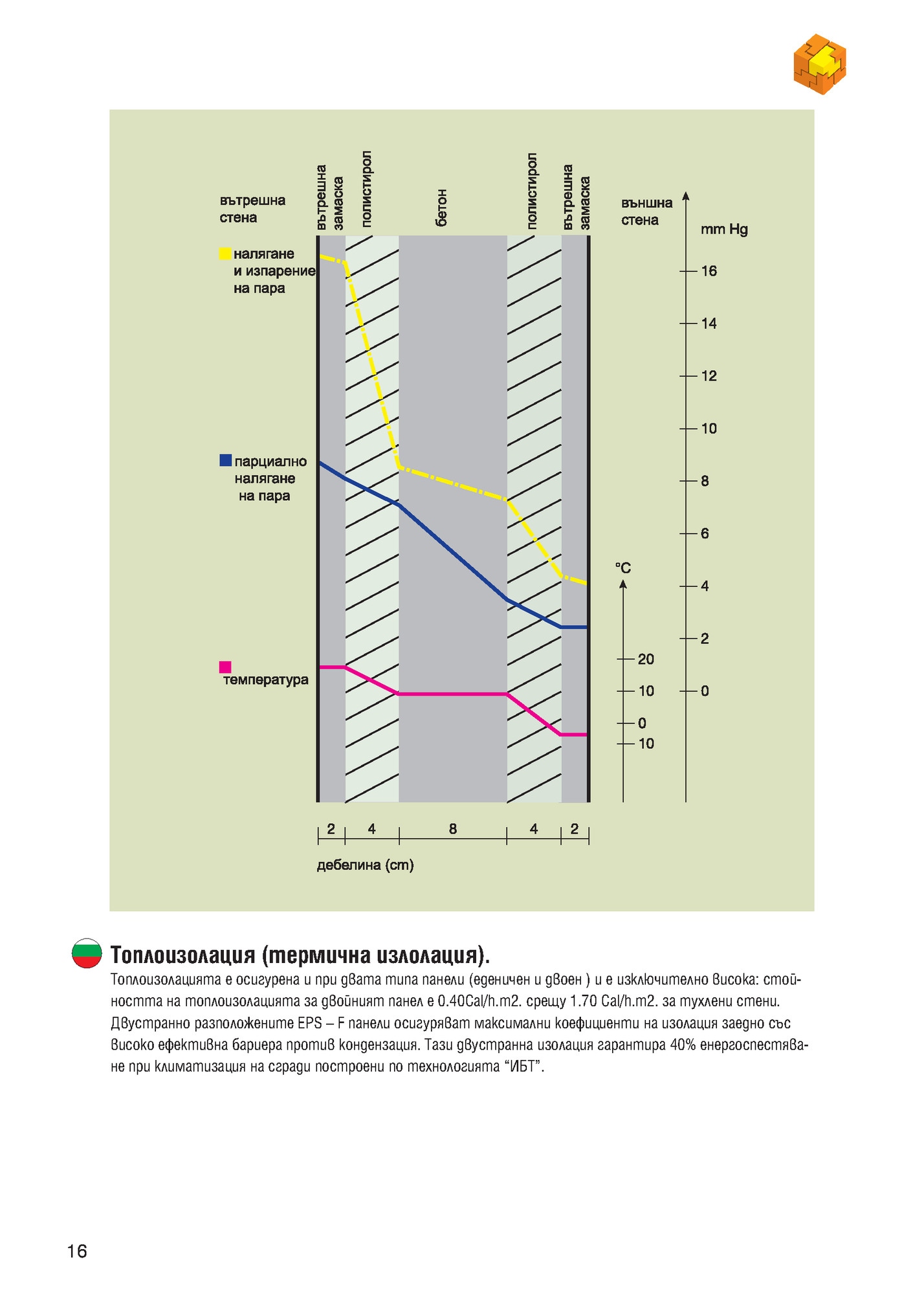

íÓÔÎÓËÁÓ·ˆËfl (ÚÂÏ˘̇ ËÁÎÓ·ˆËfl). íÓÔÎÓËÁÓ·ˆËflÚ‡  ÓÒË„ÛÂ̇ Ë ÔË ‰‚‡Ú‡ ÚËÔ‡ Ô‡ÌÂÎË (‰ÂÌ˘ÂÌ Ë ‰‚ÓÂÌ ) Ë Â ËÁÍβ˜ËÚÂÎÌÓ ‚ËÒÓ͇: ÒÚÓÈÌÓÒÚÚ‡ ̇ ÚÓÔÎÓËÁÓ·ˆËflÚ‡ Á‡ ‰‚ÓÈÌËflÚ Ô‡ÌÂÎ Â 0.40Cal/h.m2. ÒÂ˘Û 1.70 Cal/h.m2. Á‡ ÚÛıÎÂÌË ÒÚÂÌË. Ñ‚ÛÒÚ‡ÌÌÓ ‡ÁÔÓÎÓÊÂÌËÚ EPS – F Ô‡ÌÂÎË ÓÒË„Ûfl‚‡Ú χÍÒËχÎÌË ÍÓÂÙˈËÂÌÚË Ì‡ ËÁÓ·ˆËfl Á‡Â‰ÌÓ Ò˙Ò ‚ËÒÓÍÓ ÂÙÂÍÚ˂̇ ·‡Ë‡ ÔÓÚË‚ ÍÓ̉ÂÌÁ‡ˆËfl. í‡ÁË ‰‚ÛÒÚ‡Ì̇ ËÁÓ·ˆËfl „‡‡ÌÚˇ 40% ÂÌ„ÓÒÔÂÒÚfl‚‡Ì ÔË ÍÎËχÚËÁ‡ˆËfl ̇ Ò„‡‰Ë ÔÓÒÚÓÂÌË ÔÓ ÚÂıÌÓÎÓ„ËflÚ‡ “àÅí”. 16 Thermal insulation Heat insulation by both types of panels (single and double) is very high: the value of heat transmission for a double panel is 0.40Cal/h.m2. C versus 1.70 (brick walls) The polystyrene sheets ensure maximum values of insulation, together with a very eff icient condensation barrier. Such a heat insulation degree exceeds in a remarkable way the peculiar values of the partitions or curtain walls obtained with the traditional systems; this produces energy saving equal to 40% both while heating and while cooling. 17

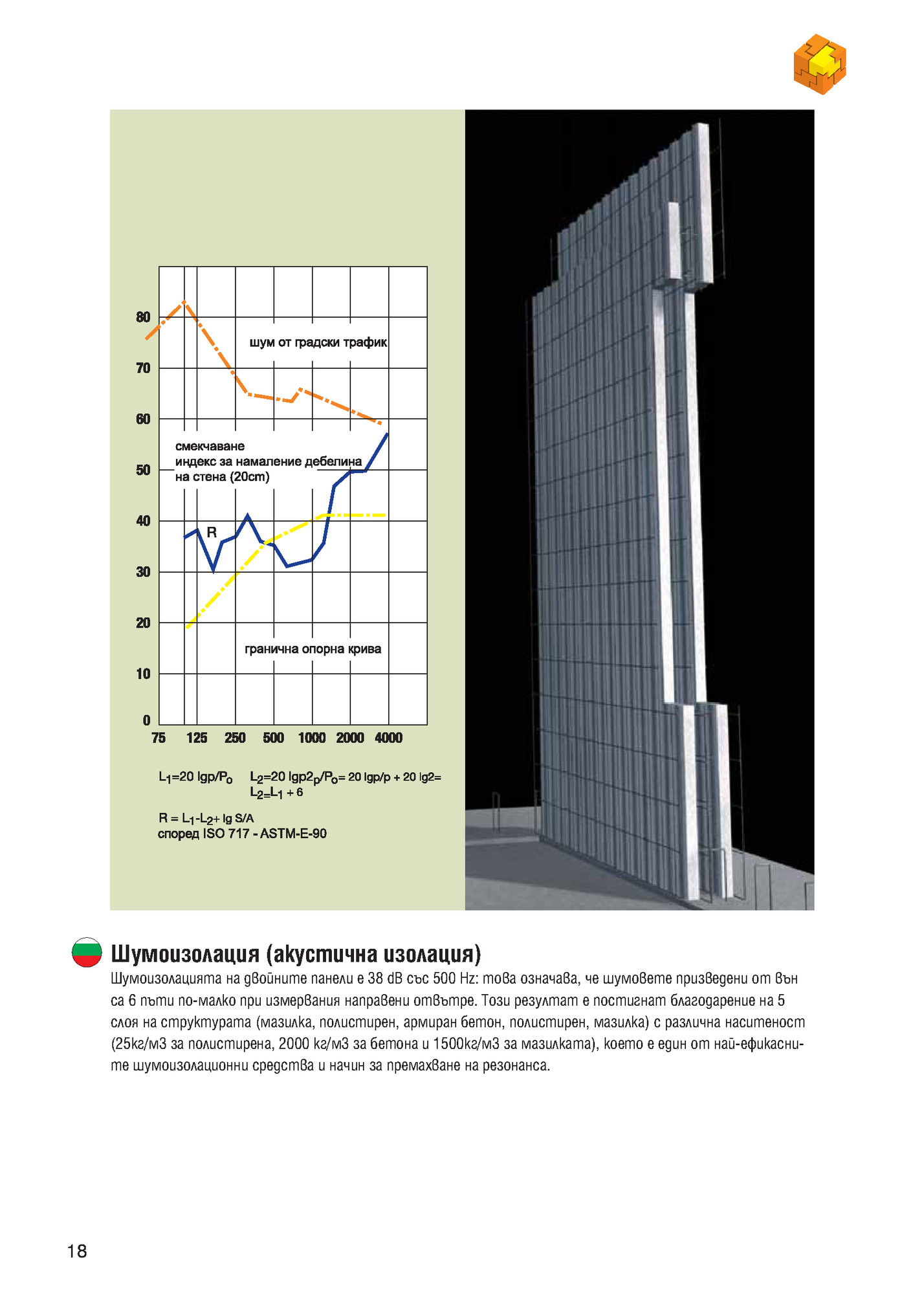

òÛÏÓËÁÓ·ˆËflÚ‡ ̇ ‰‚ÓÈÌËÚ ԇÌÂÎË Â 38 dB Ò˙Ò 500 Hz: ÚÓ‚‡ ÓÁ̇˜‡‚‡, ˜Â ¯ÛÏÓ‚ÂÚ ÔËÁ‚‰ÂÌË ÓÚ ‚˙Ì Ò‡ 6 Ô˙ÚË ÔÓ-χÎÍÓ ÔË ËÁÏ‚‡ÌËfl ̇ԇ‚ÂÌË ÓÚ‚˙ÚÂ. íÓÁË ÂÁÛÎÚ‡Ú Â ÔÓÒÚË„Ì‡Ú ·Î‡„Ó‰‡ÂÌË ̇ 5 ÒÎÓfl ̇ ÒÚÛÍÚÛ‡Ú‡ (χÁËÎ͇, ÔÓÎËÒÚËÂÌ, ‡ÏË‡Ì ·ÂÚÓÌ, ÔÓÎËÒÚËÂÌ, χÁËÎ͇) Ò ‡Á΢̇ ̇ÒËÚÂÌÓÒÚ (25Í„/Ï3 Á‡ ÔÓÎËÒÚËÂ̇, 2000 Í„/Ï3 Á‡ ·ÂÚÓ̇ Ë 1500Í„/Ï3 Á‡ χÁËÎ͇ڇ), ÍÓÂÚÓ Â Â‰ËÌ ÓÚ Ì‡È-ÂÙË͇ÒÌËÚ ¯ÛÏÓËÁÓ·ˆËÓÌÌË Ò‰ÒÚ‚‡ Ë Ì‡˜ËÌ Á‡ ÔÂχı‚‡Ì ̇ ÂÁÓ̇ÌÒ‡. 18 Acoustic insulation. The soundproof ing power of double panel is 38 dB with 500Hz: this means that noises produced outside the panel are 6 times lower on the inside. The result is achieved because the panel consists of 5 layers (plaster, polystyrene, reinforced concrete, polystyrene, plaster) with different densities (25 Kg/m3 for the polystyrene, 2000 Kg/m3 for the concrete and 1500Kg/m3 for the plaster), which is one of the most eff icient soundproof ing devices as it also avoids resonance. 19

Fleepit Digital © 2021