Channel Support Systems

The backbone of our offering Our CSS Channel Section is manufactured on our Rolling Mills in our large factory in West Bromwich Birmingham, UK and with its range of complimen-tary fixings, brackets and fasteners it represents both a cost effective and flexible solution for Mechanical and Electrical, HVAC and Metal Framing. All Strut and Bracketry products are manufactured to the standard BS6946:1988, the specification for metal channel cable support systems for electrical installations. CSS Support Systems At CSS we pride ourselves in having all the system components that you need to deliver your projects. Our ever expanding product ranges include: Channel lengths in a range of profiles in Standard lengths of 3m and 6m, and a large range of associated brackets, channel nuts and fixings to help overcome any installation challenge. It is complemented by rooftop supports, cantilever arms and our range of threaded rod and high tensile bolts. These products are widely available through our supply chain partners in a wide range of finishes that are suitable for all applications. Our offer is underpinned by our ISO 9001 Quality Management System that ensures that we continue to deliver on our customer pledge. 2

Fully Tested and Guaranteed Systems that include UK Manufactured Components It is important that we stand by the products and systems that we manufacture. We are aware how important it is that our products perform to the levels you would expect. On top of publishing Load Data that explains the performance of our Channel Sections, we have taken this one step further and had our product independently tested and accredited by the Engineering Department at Manchester University. This means that by using our system components, Section, Brackets and Fixings, Channel Nuts we are able to independently verify the performance of these products. This includes the products independently, and as a system. It also includes our threaded rod. Our offer includes a 60 Month Warranty on any CSS System Integrity. Please ask to see our Warranty document and to have it applied to your own project. 3

CSS Support Channel Our Strut lengths are rolled from Heavy Gauge (2.5mm) to light Gauge (1.5mm) steel or of a combination of these products welded back to back. CSS21/P Y X CSSBB41/P CSS41/P Y X X CSS41/S Y X Y X Y Y X Y CSS21/S X X X X Y Y Y All our strut products are manufactured to conform to BS6946:1988, the British Standard for Metal Channel Support Systems for Electrical Installations. Our products have been fully tested by an independent testing house to verify the Safe Working Load (SWL). They also tested for both Pull out and Slip of the Channel nuts when the products are used as a complete system. It is always recommended that the system is Installed as a whole (Channel, Brackets, Fixings) to guarantee system integrity, maximise performance and to meet the latest building safety requirements. The material used in CSS Strut has a minimum yield strength of 280N/mm² and a minimum ultimate strength of 350N/mm². Our load and deflection calculations are calculated using a safety factor of 1.6 to determine a safe working load. Beam loads are calculated from the column face to BS EN 1993. Finishes : Channel and Brackets Suffix Type PG MS Mild Steel BS EN 10025 GA Mild Steel Hot Dip Galvanised after manufacture to BS EN 1461:2009 approx. 55 microns of Zinc ZP Zinc Plated to EN12329 SS Stainless Steel 316L 1.4404 MG Magnelis is self healing and has a coating of Zinc, Aluminium and Magnesium ZD 4 Pregalvanised to BS EN 10346 approx. 21 microns of Zinc Zinc Dicromate used in Data Centres, Clean Environments, yellow plated finish

BS6946:1988—The Standard All our strut products are manufactured to conform to BS6946:1988, the British Standard for Metal Channel Support Systems for Electrical Installations. Sectional Dimensions The Standard mandates that channel sections must conform to the specified dimensional criteria when measured at a distance of no less than 150mm from the end. The permissible twist shall not exceed 2.5 degrees per metre. Bowing is allowed within the standard, but must not exceed 5mm for channels measuring 3m in length and 10mm for those measuring 6m, with measurements taken at the midpoint of the length . All dimensions are in conformance with BS6946:1988, the British Standard for Metal Channel Support Systems for Electrical Installations. Twist Bow Safe Working Slip and Pull-Out Loads These loads have been established through testing conducted in accordance with the procedures outlined in section 8 of the standard. It is important to emphasize that channel nuts are essential components of the system, and various imported products may not possess equivalent load capacities; therefore, they should not be intermixed with our own fully tested systems. Marking CSS channels are systematically marked at regular intervals during the production process. The standard stipulates that the manufacturer’s name and BS 6946:1988 must be included. At CSS we engrave this in with our unique identification code on both our support channels along with our branding. Brackets require the boxes to be marked but we also mark the product with CSS and a unique manufacture reference, to offer full and unique system traceability. Combination Channels Channels that are required in various configurations, such as back-to-back channels, are typically supplied with spot welding as the standard practice. It is crucial that these channels are fully supported at both ends beneath the bottom face, and loads should never be suspended solely from the return edges of the bottom channel. Seam welded product is available in a number of finishes as a optional extra. 5

Material Specification Strut channels are generally manufactured from Pregalvanised Steel BS EN10346, as a base in Mild Steel BS EN 10025, in Stainless Steel 316L, and in Magnellis Zinc Magnesium. Finishes to the mild steel product include Hot Dip Galvanising to BS EN 4161, yellow Zinc Dicromate, powder coating and other finishes upon request. Brackets generally are manufactured from Mild Steel BS EN 10025, and Hot Dipped Galvanised to BS EN 1461, but are available in other finishes including Stainless Steel, and Zinc Plated. Fixings Channel Nuts, Bolts and Washers, are manufactured from steel complying with the DIN standard 933/938 are zinc plated and passivated or available in Hot Dip Galv BS EN 1461, or in Stainless Steel A2 or A4. Threaded Rod and Studding. All our threaded rod has a minimum of 55° pitch, Zinc Plated to DIN 976, with tested guaranteed and independently verified performance. Standard tensile grade is 4.6 but 8.8 is also available. Channel Thickness The standard covers material with thicknesses of 1.5mm and 2.5mm Material. Caution should be taken when referring to any other material that is manufactured outside the standard as it has no performance criteria. Load Tables Load tables are provided alongside the specific channel sections depicted on pages 9-16. Design Notes Minimum material stress is 280Nmm² with Z28 Material. Channel Section and Brackets Safe Working Loads (SWL) are calculated in accordance with BS 5950. Beams calculations assume that the beams are simply supported and laterally restrained. The beam loads are supplied through the centre of the Channel in the direction shown on the specific load table. There are further load tables provided for a (UDL) uniformed distributed load or a concentrated or point load (PL). Beam loads and deflections are calculated at a stress od 175Nmm² using a Safety Factor of 1.6 to determine the safe working loads. Alternative Safe working loads are Limited Deflection Load (Span/200) – Load which produces a deflection of 1/200th of the span, (this is the load most commonly used as it produces an acceptable degree of deflection.) Alternatively 1/360th of the span where the deflection is hardly visible. It is at the discretion of the designer to recommend which table to use especially where deflections are critical. Collum face loads are generally supplied at the open face of the strut channel and a load applied. There are Safe Working Load published at the centroid and at the slot face. Other materials The load tables are based upon our standard range finished in Pregalv. The mechanical properties of the other finishes and materials listed as options are available upon request. 6

Strut Channel Support Systems. 7

Channel Sections Channel Section manufactured on our mills by our people. It is important especially on a product that underpins and supports 90% of the services, that you understand where this product comes from. Quite simply, we have control of these products because we passionately manufacture them ourselves with full traceability and our enhanced quality procedures. 8

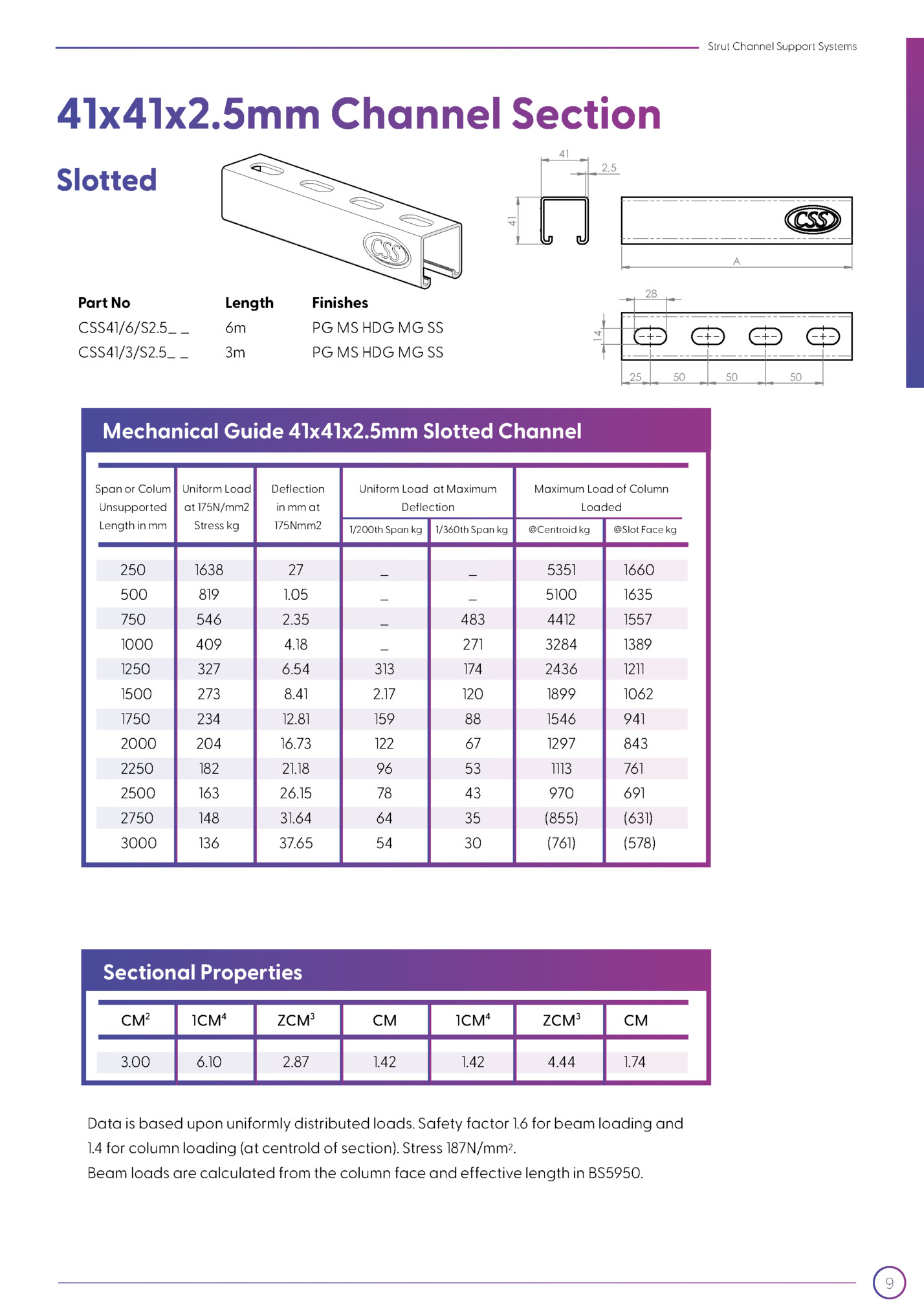

41x41x2.5mm Channel Section 41 41 2,5 2,5 41 41 41 Slotted 2,5 41 A A A 28 Finishes 6m PG MS HDG MG SS CSS41/3/S2.5_ _ 3m PG MS HDG MG SS 28 28 14 CSS41/6/S2.5_ _ 14 Length 14 Part No 25 50 25 25 50 50 50 50 50 50 50 50 Mechanical Guide 41x41x2.5mm Slotted Channel Span or Colum Uniform Load Deflection Uniform Load at Maximum Maximum Load of Column Unsupported at 175N/mm2 in mm at Deflection Loaded Length in mm Stress kg 175Nmm2 1/200th Span kg 1/360th Span kg @Centroid kg @Slot Face kg 250 1638 27 _ _ 5351 1660 500 819 1.05 _ _ 5100 1635 750 546 2.35 _ 483 4412 1557 1000 409 _ 271 3284 1389 1250 327 6.54 313 174 2436 1211 1500 273 8.41 2.17 120 1899 1062 1750 234 12.81 159 88 1546 941 2000 204 16.73 122 67 1297 843 2250 182 21.18 96 53 1113 761 2500 163 26.15 78 43 970 691 2750 148 31.64 64 35 (855) (631) 3000 136 37.65 54 30 (761) (578) 4.18 Sectional Properties CM2 1CM4 ZCM3 CM 1CM4 ZCM3 CM 3.00 6.10 2.87 1.42 1.42 4.44 1.74 Data is based upon uniformly distributed loads. Safety factor 1.6 for beam loading and 1.4 for column loading (at centrold of section). Stress 187N/mm2. Beam loads are calculated from the column face and effective length in BS5950. 9

Fleepit Digital © 2021