CLEAN SYSTEMS CEILING GRID AND PANEL SYSTEMS PHARMACEUTICAL SEMICONDUCTOR LIFE SCIENCES LABORATORIES MEDICAL DEVICE HEALTHCARE FOR CLEAN AND CONTROLLED ENVIRONMENTS www.astracleansystems.com

Astra CONTENTS CLEAN SYSTEMS Astra Technologies UK is a market leader in cleanroom products CLEAN SYSTEMS CONTENTS CEILING GRID COMPARISON CHART 4 ACS-ALU70 HONEYCOMB PANEL 12 ACS-T50 GRID 5 CHEQUER PLATE PANEL FINISH 12 ACS-T56 GRID 5 ACS WALL PANELS 13 ACS-T56N GRID 6 GRID AND PANEL SAMPLES 13 ACS-T56 PRO GRID 6 LOAD AND IMPACT TESTING 14 ACS-T56N PRO GRID 7 CERTIFICATIONS 14 ACS-T56 PRO 100 GRID 7 EVOTEK 15 AC-T56N PRO 100 GRID 8 G60N GRID 8 T56 PRO BEARING RAIL SYSTEM 9 pharmaceutical, biotechnology, ACS-ALU06 HONEYCOMB PANEL 9 ACS-ALU12 HONEYCOMB PANEL 10 semiconductor, medical device and data ACS-ALU25 HONEYCOMB PANEL 10 centre applications. ACS-ALU30 HONEYCOMB PANEL 11 ACS-ALU50 HONEYCOMB PANEL 11 for advanced technology facilities. 45 YEARS of manufacturing experience for clean and controlled environments including WORLD CLASS 2 WORLDWIDE www.astracleansystems.co.uk www.astracleansystems.co.uk 3

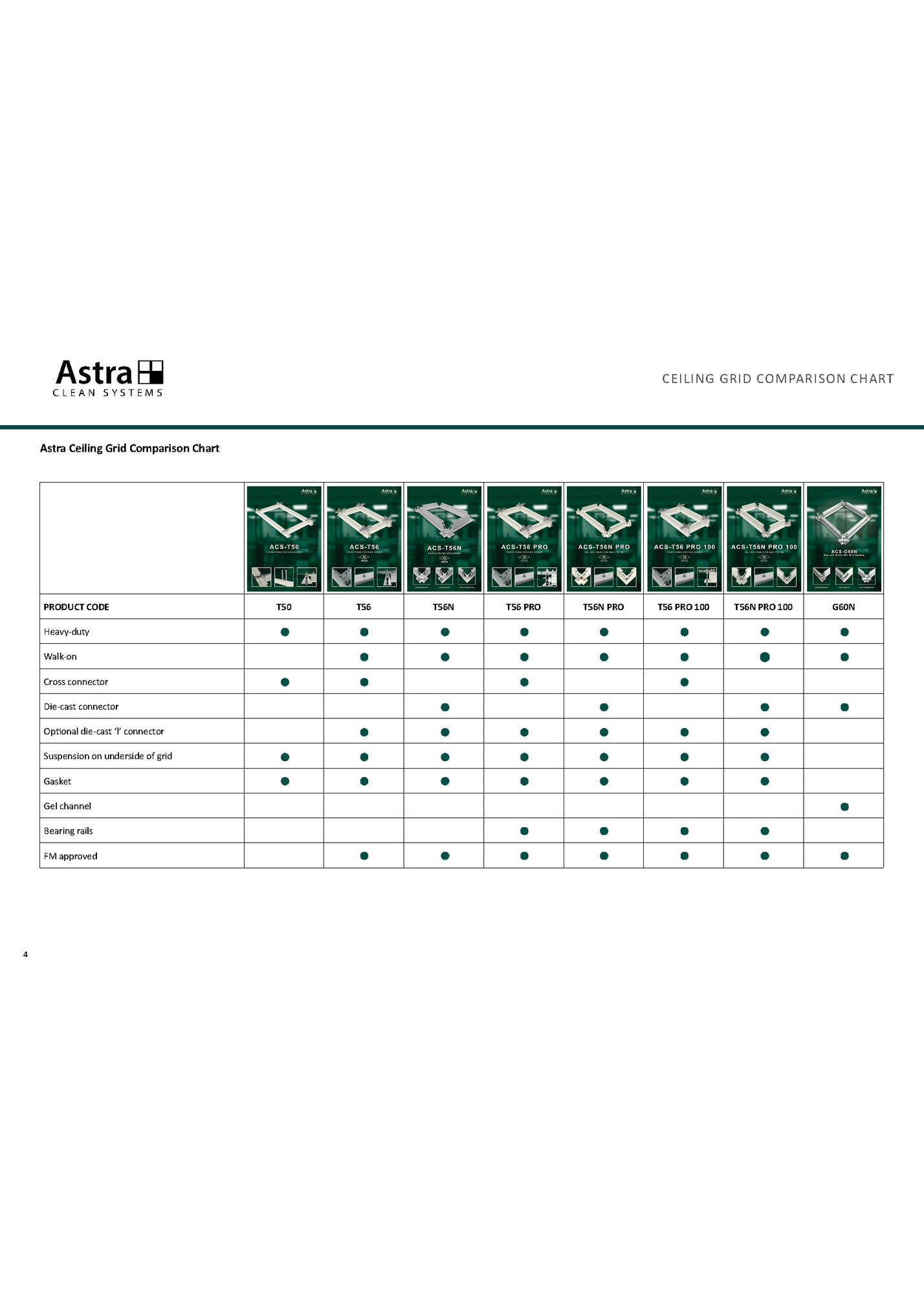

CEILING GRID COMPARISON CHART CLEAN SYSTEMS Astra PRODUCT RANGE CLEAN SYSTEMS ACS-T50 Astra Ceiling Grid Comparison Chart ACS-T56 CROSS CONNECTOR GRID SYSTEM CROSS CONNECTOR GRID SYSTEM Designed as a non-walk-on frame construction with high deflection strength, consisting of 50mm (2”) wide aluminium extrusion main and cross tees of identical shape. Installation is both quick and simple, utilising cross connectors and T-bolt fasteners to keep the installation time to a minimum. Designed as a walk-on frame construction with high deflection strength, consisting of 56mm (2-7/32”) wide aluminium extrusion main tee and cross tees of identical shape, joined together with aluminium cross connectors. The T56 aluminium tee and cross tees come with a continuous channel for T-bolt fasteners at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with a T-bolt. The T50 aluminium main tees and cross tees come with a concealed screw slot channel at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with an M6 (1/4”) bolt/screw. The frame construction allows for standard grid modules of 1200 x 1200mm, 1200 x 600mm, 4’ x 4’ and 4’ x 2’, however other grid sizes can also be provided. The frame construction allows for standard grid modules of 1225 x 1225mm, 1225 x 625mm, 48” x 48” and 48” x 24”, however other grid sizes can also be provided. PRODUCT CODE T50 T56 T56N T56 PRO T56N PRO T56 PRO 100 T56N PRO 100 The T56 ceiling grid has an ultimate uniformly distributed load of 200kg/m² (41lb/ft²) on the ceiling panel. L/360 deflection with point load of 125KG on the ceiling grid for the applied load during maintenance. The grid system is designed for an ultimate uniformly distributed load of 45kg/m2 (9.21lb/sf). All additional loads must be directly suspended to the secondary support structure. G60N Heavy-duty Walk-on Cross connector Die-cast connector Optional die-cast ‘l’ connector Suspension on underside of grid 15mm (19/32”) Specification 20mm (51/64”) Specification • 4 Cross connectors with T-bolt fasteners • Aluminium cross connectors Concealed M6 (1/4”) screw slot channel • Provides tight seal and accurate alignment • Provides tight seal and alignment • Continuous channel for T-bolt fasteners RAL 9003 Powder-coated finish • Anodised finish and powder-coated options Compatible FFUs and Lighting available • Compatible FFUs and Lighting available • 50mm (2”) Point load of 125kg (L360) • FM approved • • 42.6mm (1 43/64”) Simple and adaptable installation • Bearing rails Walk-on aluminium grid system • Gel channel • • Gasket Non-walk-on aluminium grid system Factory-applied gasket option • Optional die-cast connectors for fire sprinklers • FM Approved 70mm (2-3/4”) 56mm (2-7/32”) 5

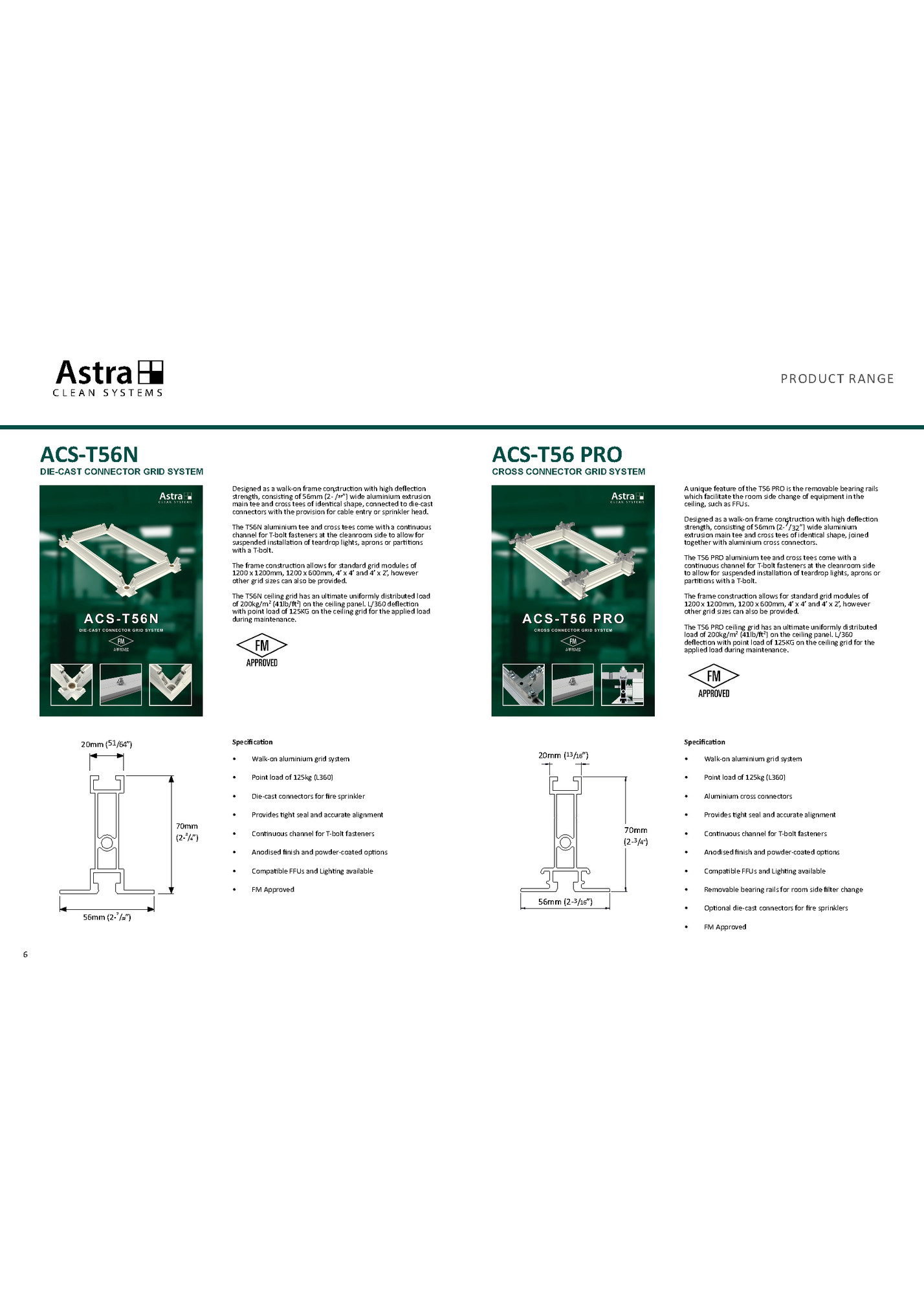

PRODUCT RANGE CLEAN SYSTEMS ACS-T56N ACS-T56 PRO DIE-CAST CONNECTOR GRID SYSTEM CLEAN SYSTEMS ACS-T56N PRO CROSS CONNECTOR GRID SYSTEM Designed as a walk-on frame construction with high deflection strength, consisting of 56mm (2-7/32”) wide aluminium extrusion main tee and cross tees of identical shape, connected to die-cast connectors with the provision for cable entry or sprinkler head. Astra PRODUCT RANGE ACS-T56 PRO 100 DIE-CAST CONNECTOR GRID SYSTEM CROSS CONNECTOR GRID SYSTEM A unique feature of the T56 PRO is the removable bearing rails which facilitate the room side change of equipment in the ceiling, such as FFUs. A unique feature of the T56N PRO is the removable bearing rails which facilitate the room side change of equipment in the ceiling, such as FFUs. A unique feature of the T56 PRO 100 is the removable bearing rails which facilitate the room side change of equipment in the ceiling, such as FFUs. Designed as a walk-on frame construction with high deflection strength, consisting of 56mm (2-7/32”) wide aluminium extrusion main tee and cross tees of identical shape, joined together with aluminium cross connectors. Designed as a walk-on frame construction with high deflection strength, consisting of 56mm (2-7/32”) wide aluminium extrusion main tee and cross tees of identical shape, connected to die-cast connectors with the provision for cable entry or sprinkler head. Designed as a walk-on frame construction with high deflection strength, consisting of 56mm (2-7/32”) wide aluminium extrusion main tee and cross tees of identical shape, joined together with aluminium cross connectors. The frame construction allows for standard grid modules of 1200 x 1200mm, 1200 x 600mm, 4’ x 4’ and 4’ x 2’, however other grid sizes can also be provided. The T56 PRO aluminium tee and cross tees come with a continuous channel for T-bolt fasteners at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with a T-bolt. The T56N PRO aluminium tee and cross tees come with a continuous channel for T-bolt fasteners at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with a T-bolt. The T56 PRO 100 aluminium tee and cross tees come with a continuous channel for T-bolt fasteners at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with a T-bolt. The T56N ceiling grid has an ultimate uniformly distributed load of 200kg/m² (41lb/ft²) on the ceiling panel. L/360 deflection with point load of 125KG on the ceiling grid for the applied load during maintenance. The frame construction allows for standard grid modules of 1200 x 1200mm, 1200 x 600mm, 4’ x 4’ and 4’ x 2’, however other grid sizes can also be provided. The frame construction allows for standard grid modules of 1200 x 1200mm, 1200 x 600mm, 4’ x 4’ and 4’ x 2’, however other grid sizes can also be provided. The frame construction allows for standard grid modules of 1200 x 1200mm, 1200 x 600mm, 4’ x 4’ and 4’ x 2’, however other grid sizes can also be provided. The T56 PRO ceiling grid has an ultimate uniformly distributed load of 200kg/m² (41lb/ft²) on the ceiling panel. L/360 deflection with point load of 125KG on the ceiling grid for the applied load during maintenance. The T56N PRO ceiling grid has an ultimate uniformly distributed load of 200kg/m² (41lb/ft²) on the ceiling panel. L/360 deflection with a point load of 125KG on the ceiling grid for the applied load during maintenance. L/360 deflection with point load of 500KG suitable for high-load AMHS applications. Specification Specification Specification The T56N aluminium tee and cross tees come with a continuous channel for T-bolt fasteners at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with a T-bolt. 20mm (51/64”) • Walk-on aluminium grid system • • • 70mm (2-3/4”) Point load of 125kg (L360) 13/16" 20mm 13/16" Walk-on aluminium grid system Point load of 125kg (L360) Die-cast connectors for fire sprinkler • Provides tight seal and accurate alignment • 20mm 20mm20mm /16”) (13 • Continuous channel for T-bolt fasteners Anodised finish and powder-coated options Compatible FFUs and Lighting available • FM Approved 70mm (2-3/4") 56mm 2-3/16" 56mm (2-3/16”) 2-3/16" • Compatible FFUs and Lighting available • Removable bearing rails for room side filter change • Optional die-cast connectors for fire sprinklers • FM Approved 56mm 2-3/16" 56mm 56mm 2-3/16" 56mm (2-3/16”) 2-3/16" • Point load of 500kg (L360) Provides tight seal and accurate alignment • Aluminium cross connectors Continuous channel for T-bolt fasteners • Provides tight seal and accurate alignment • Anodised finish and powder-coated options • Continuous channel for T-bolt fasteners Compatible FFUs and Lighting available • Anodised finish and powder-coated options • Anodised finish and powder-coated options Die-cast connectors for fire sprinkler • Continuous channel for T-bolt fasteners • 56mm 2-3/16" 56mm • Walk-on aluminium grid system • 70mm (2-3/4") 70mm 70mm 70mm 2-3/4" 2-3/4" 2-3/4" • • 13/16" Walk-on aluminium grid system • 13/16" 20mm Provides tight seal and accurate alignment 70mm 70mm 70mm 2-3/4" 2-3/4" 2-3/4" Specification • 13/16" Aluminium cross connectors • 6 • 13/16" • • 56mm (2-7/32”) 20mm 20mm20mm /16”) (13 22mm (55/64”) Removable bearing rails for room side filter change • Compatible FFUs and Lighting available • FM Approved • Removable bearing rails for room side filter change • Optional die-cast connectors for fire sprinklers • FM Approved 100mm (4”) 56mm (2-7/32”) 7

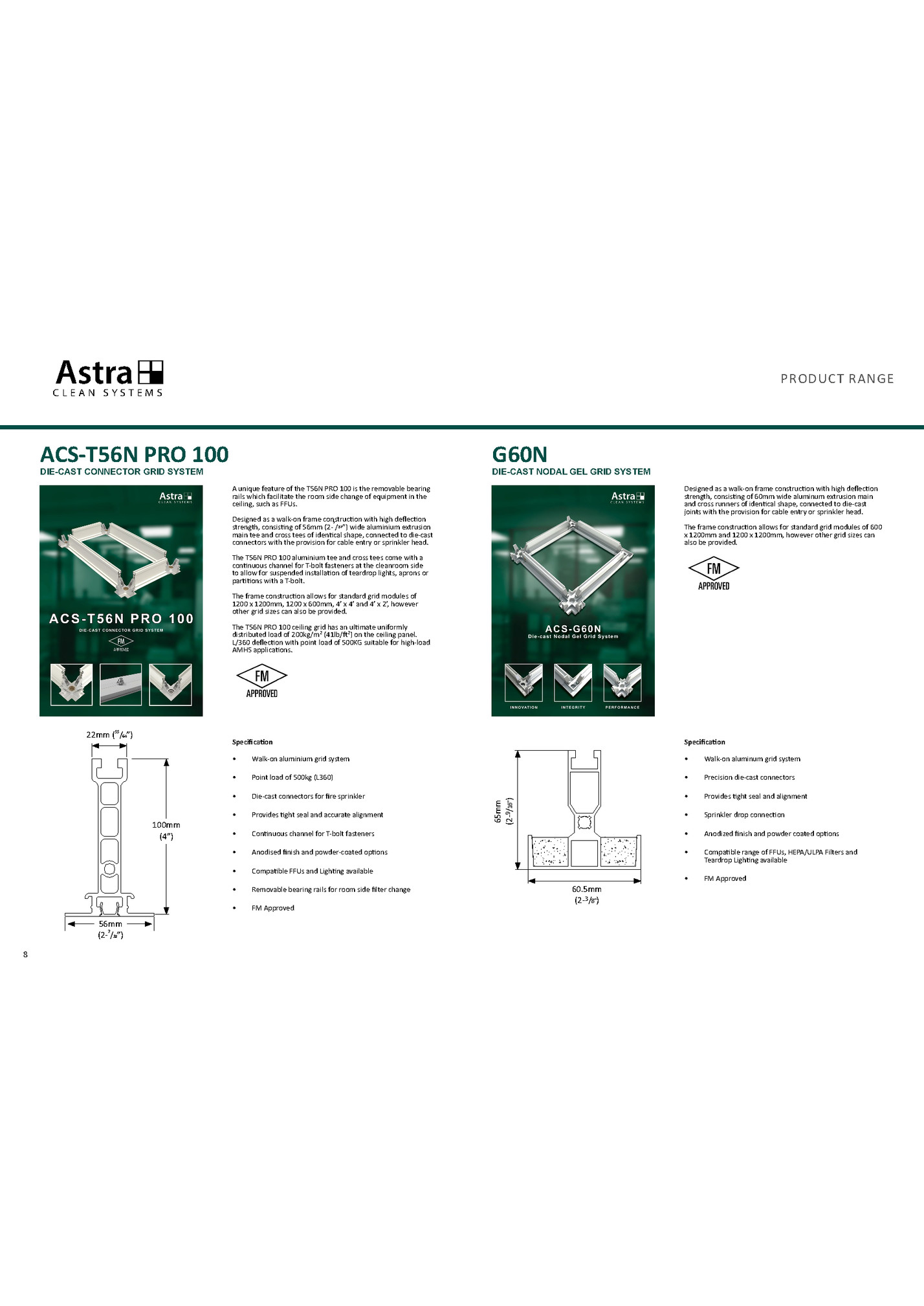

PRODUCT RANGE CLEAN SYSTEMS ACS-T56N PRO 100 G60N DIE-CAST CONNECTOR GRID SYSTEM Astra PRODUCT RANGE CLEAN SYSTEMS T56 PRO Bearing Rail System DIE-CAST NODAL GEL GRID SYSTEM Designed as a walk-on frame construction with high deflection strength, consisting of 60mm wide aluminum extrusion main and cross runners of identical shape, connected to die-cast joints with the provision for cable entry or sprinkler head. A unique feature of the T56N PRO 100 is the removable bearing rails which facilitate the room side change of equipment in the ceiling, such as FFUs. Designed as a walk-on frame construction with high deflection strength, consisting of 56mm (2-7/32”) wide aluminium extrusion main tee and cross tees of identical shape, connected to die-cast connectors with the provision for cable entry or sprinkler head. A unique feature of the T56 PRO is the removable bearing rails which facilitate the room side change of equipment in the ceiling (such as FFUs). This is particularly useful for non-walk-on ceilings or projects with restricted access to the plenum area. FFUs can be installed from the under side of the ceiling and also accessed for maintenance by removing the bearing rail. ACS-ALU06 6MM ALUMINIUM HONEYCOMB CEILING PANEL ACS-ALU06 Aluminium honeycomb panels are heavy-duty nonwalk-on panels which are designed specifically to integrate with the ACS range of ceiling grid systems. Both light and strong, the aluminium honeycomb panels have one of the best strength-to-weight ratios of any construction materials available today and have been developed to meet the exacting requirements of the cleanroom industry. The frame construction allows for standard grid modules of 600 x 1200mm and 1200 x 1200mm, however other grid sizes can also be provided. The T56N PRO 100 aluminium tee and cross tees come with a continuous channel for T-bolt fasteners at the cleanroom side to allow for suspended installation of teardrop lights, aprons or partitions with a T-bolt. The ACS-ALU06 panels are well suited to semi-conductor, aerospace, optical and high-technology applications, with zero out-gassing and a durable ESD or NSD roller-coated paint finish. A range of standard panel sizes is available, however other sizes can be custom made to order. The frame construction allows for standard grid modules of 1200 x 1200mm, 1200 x 600mm, 4’ x 4’ and 4’ x 2’, however other grid sizes can also be provided. Simple to install with minimal labour requirements on site, the ACS-ALU06 panels together with the ACS range of ceiling grid systems provide a cost-effective, highly durable and lowmaintenance ceiling system. The T56N PRO 100 ceiling grid has an ultimate uniformly distributed load of 200kg/m² (41lb/ft²) on the ceiling panel. L/360 deflection with point load of 500KG suitable for high-load AMHS applications. T56 PRO Grid without bearing rails Certification T56 PRO Grid with bearing rails • • 22mm (55/64”) Specification • Walk-on aluminium grid system • • Point load of 500kg (L360) • Precision die-cast connectors • Die-cast connectors for fire sprinkler • Provides tight seal and alignment • • Provides tight seal and accurate alignment • Continuous channel for T-bolt fasteners • Anodized finish and powder coated options Anodised finish and powder-coated options • Compatible range of FFUs, HEPA/ULPA Filters and Teardrop Lighting available • Compatible FFUs and Lighting available • Removable bearing rails for room side filter change • FM Approved 60.5mm (2-3/8") • FM Approved FFU Face material - 0.5mm (25 gauge) thick steel sheet on both sides • Core material - 5mm (3/16”) thick aluminum honeycomb • FFU Adhesive - Thermosetting epoxy adhesive • FFU positioned on removable bearing rail to facilitate both installation and maintenance from the room side. Approval Identification: PR459442 Technical Data • Sprinkler drop connection • 100mm (4”) FFU Walk-on aluminum grid system 65mm (2-9/16") Specification FM Approvals Class: 4882 Outgassing - Zero out-gassing Options • NSD (non-static dissipative) coating • ESD (electrostatic dissipative – 106-108Ω) coating • Custom-made sizes: the maximum length for 6mm thick honeycomb panels, with a width of 1200mm, is 2980mm - see page 13. 56mm (2-7/32”) 8 9 CG 7200-C

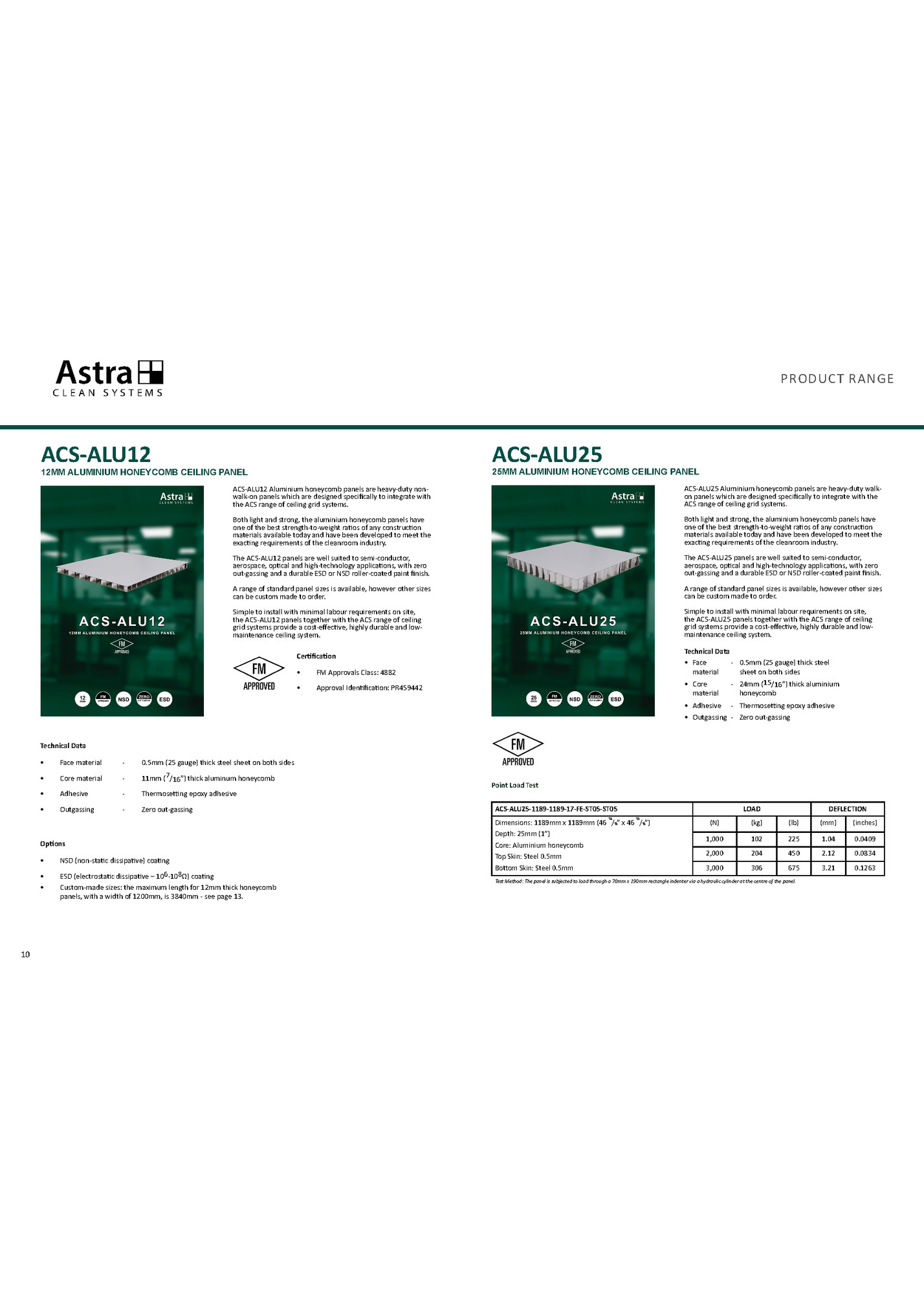

PRODUCT RANGE CLEAN SYSTEMS ACS-ALU25 ACS-ALU12 CLEAN SYSTEMS ACS-ALU30 25MM ALUMINIUM HONEYCOMB CEILING PANEL 12MM ALUMINIUM HONEYCOMB CEILING PANEL Astra PRODUCT RANGE ACS-ALU50 30MM ALUMINIUM HONEYCOMB CEILING PANEL 50MM ALUMINIUM HONEYCOMB CEILING PANEL ACS-ALU12 Aluminium honeycomb panels are heavy-duty nonwalk-on panels which are designed specifically to integrate with the ACS range of ceiling grid systems. ACS-ALU25 Aluminium honeycomb panels are heavy-duty walkon panels which are designed specifically to integrate with the ACS range of ceiling grid systems. ACS-ALU30 Aluminium honeycomb panels are heavy-duty walkon panels which are designed specifically to integrate with the ACS range of ceiling grid systems. ACS-ALU50 Aluminium honeycomb panels are heavy-duty walkon panels which are designed specifically to integrate with the ACS range of ceiling grid system. Both light and strong, the aluminium honeycomb panels have one of the best strength-to-weight ratios of any construction materials available today and have been developed to meet the exacting requirements of the cleanroom industry. Both light and strong, the aluminium honeycomb panels have one of the best strength-to-weight ratios of any construction materials available today and have been developed to meet the exacting requirements of the cleanroom industry. Both light and strong, the aluminium honeycomb panels have one of the best strength-to-weight ratios of any construction materials available today and have been developed to meet the exacting requirements of the cleanroom industry. Both light and strong, the aluminium honeycomb panels have one of the best strength-to-weight ratios of any construction materials available today and have been developed to meet the exacting requirements of the cleanroom industry. The ACS-ALU12 panels are well suited to semi-conductor, aerospace, optical and high-technology applications, with zero out-gassing and a durable ESD or NSD roller-coated paint finish. The ACS-ALU25 panels are well suited to semi-conductor, aerospace, optical and high-technology applications, with zero out-gassing and a durable ESD or NSD roller-coated paint finish. The ACS-ALU30 panels are well suited to semi-conductor, aerospace, optical and high-technology applications, with zero out-gassing and a durable ESD or NSD roller-coated paint finish. The ACS-ALU50 panels are well suited to semi-conductor, aerospace, optical and high-technology applications, with zero out-gassing and a durable ESD or NSD roller-coated paint finish. A range of standard panel sizes is available, however other sizes can be custom made to order. A range of standard panel sizes is available, however other sizes can be custom made to order. A range of standard panel sizes is available, however other sizes can be custom made to order. A range of standard panel sizes is available, however other sizes can be custom made to order. Simple to install with minimal labour requirements on site, the ACS-ALU12 panels together with the ACS range of ceiling grid systems provide a cost-effective, highly durable and lowmaintenance ceiling system. Simple to install with minimal labour requirements on site, the ACS-ALU25 panels together with the ACS range of ceiling grid systems provide a cost-effective, highly durable and lowmaintenance ceiling system. Simple to install with minimal labour requirements on site, the ACS-ALU30 panels together with the ACS range of ceiling grid systems provide a cost-effective, highly durable and lowmaintenance ceiling system. Simple to install with minimal labor requirements on site, the ACS-ALU50 panels together with the ACS range of ceiling grid systems provide a cost-effective, highly durable and lowmaintenance ceiling system. Technical Data • Face - 0.5mm (25 gauge) thick steel material sheet on both sides • Core - 24mm (15/16”) thick aluminium material honeycomb Technical Data • Face - 0.5mm (25 gauge) thick steel material sheet on both sides • Core - 29mm (1-5/32”) thick aluminium material honeycomb Technical Data • Face - 0.5mm (25 gauge) thick steel material sheet on both sides • Core - 49mm (1-15/16”) thick aluminium material honeycomb • Adhesive • Adhesive • Adhesive Certification • FM Approvals Class: 4882 • Approval Identification: PR459442 - Thermosetting epoxy adhesive • Outgassing - Zero out-gassing - Thermosetting epoxy adhesive • Outgassing - Zero out-gassing - Thermosetting epoxy adhesive • Outgassing - Zero out-gassing Technical Data • Face material - 0.5mm (25 gauge) thick steel sheet on both sides • Core material - 11mm (7/16”) thick aluminum honeycomb • Adhesive - Thermosetting epoxy adhesive • Outgassing - Zero out-gassing Options • • • 10 NSD (non-static dissipative) coating ESD (electrostatic dissipative – 106-108Ω) coating Custom-made sizes: the maximum length for 12mm thick honeycomb panels, with a width of 1200mm, is 3840mm - see page 13. Point Load Test Point Load Test ACS-ALU25-1189-1189-17-FE-ST05-ST05 Dimensions: 1189mm x 1189mm (46 13/16” x 46 13/16”) Depth: 25mm (1”) Core: Aluminium honeycomb Top Skin: Steel 0.5mm Bottom Skin: Steel 0.5mm LOAD (N) (kg) DEFLECTION (lb) (mm) (inches) 1,000 102 225 1.04 0.0409 2,000 204 450 2.12 0.0834 3,000 306 675 3.21 0.1263 Test Method: The panel is subjected to load through a 70mm x 190mm rectangle indenter via a hydraulic cylinder at the centre of the panel. ACS-ALU30-1189-1189-17-FE-ST05-ST05 Dimensions: 1189mm x 1189mm (46 13/16” x 46 13/16”) Depth: 30mm (1-3/16”) Core: Aluminium honeycomb Top Skin: Steel 0.5mm Bottom Skin: Steel 0.5mm Point Load Test LOAD DEFLECTION (N) (kg) (lb) (mm) (inches) 1,000 102 225 0.84 0.0330 2,000 204 450 1.69 0.0665 3,000 306 675 2.56 0.1007 Test Method: The panel is subjected to load through a 70mm x 190mm rectangle indenter via a hydraulic cylinder at the centre of the panel. ACS-ALU50-1189-1189-17-FE-ST05-ST05 Dimensions: 1189mm x 1189mm (46 13/16” x 46 13/16”) Depth: 50mm (2”) Core: Aluminium honeycomb Top Skin: Steel 0.5mm Bottom Skin: Steel 0.5mm LOAD DEFLECTION (N) (kg) (lb) (mm) (inches) 1,000 102 225 0.88 0.0346 2,000 204 450 1.3 0.0511 3,000 306 675 1.65 0.0649 Test Method: The panel is subjected to load through a 70mm x 190mm rectangle indenter via a hydraulic cylinder at the centre of the panel. 11

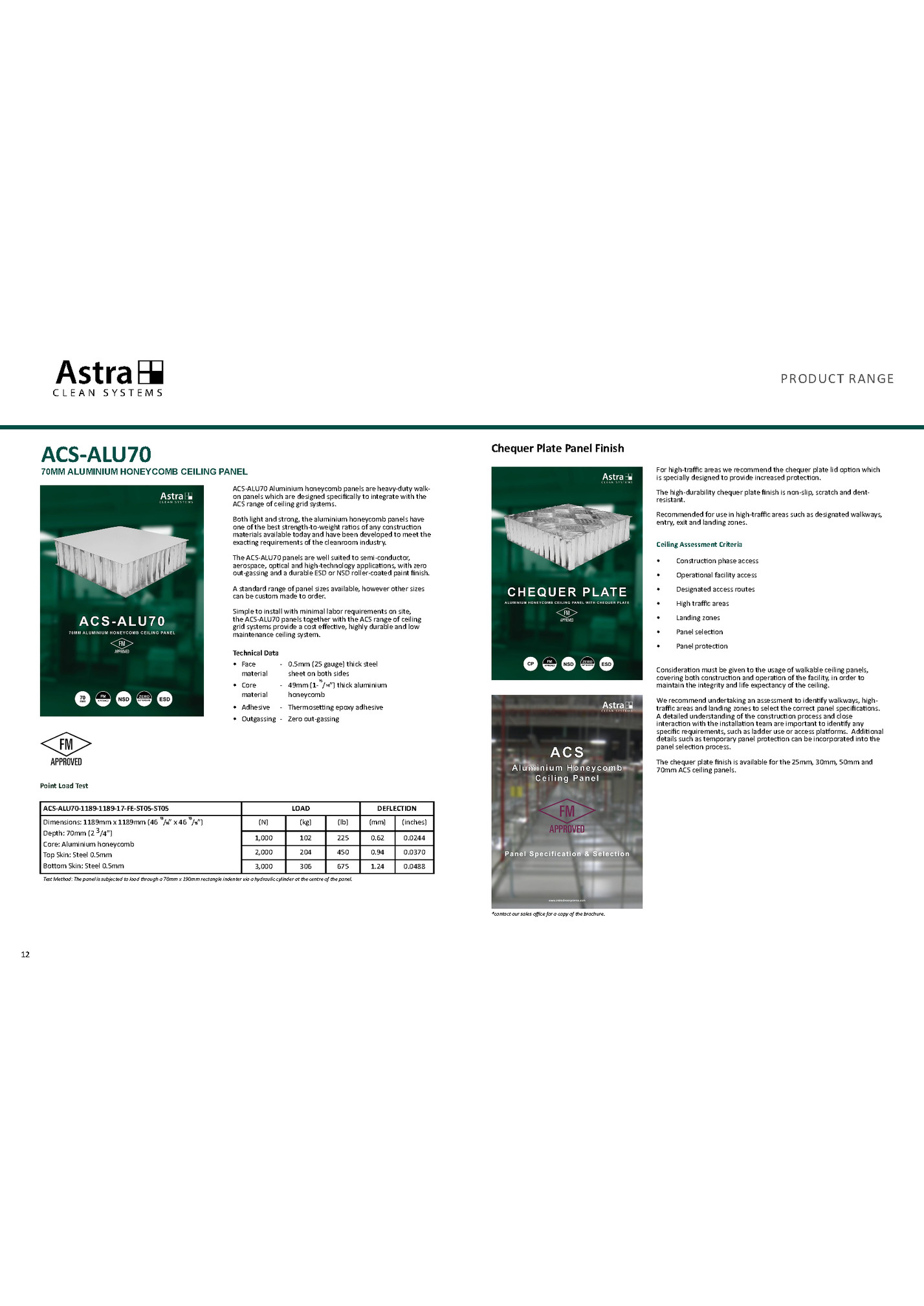

PRODUCT RANGE CLEAN SYSTEMS ACS-ALU70 Chequer Plate Panel Finish ACS-ALU70 Aluminium honeycomb panels are heavy-duty walkon panels which are designed specifically to integrate with the ACS range of ceiling grid systems. Sample Set-Up The ACS range of 6mm and 12mm honeycomb panels are well-suited for a large range of applications, including divider walls, plenum walls and skin walls for covering existing surfaces. The high-durability chequer plate finish is non-slip, scratch and dentresistant. Recommended for use in high-traffic areas such as designated walkways, entry, exit and landing zones. Both light and strong, the aluminium honeycomb panels have one of the best strength-to-weight ratios of any construction materials available today and have been developed to meet the exacting requirements of the cleanroom industry. CLEAN SYSTEMS ACS Wall Panels For high-traffic areas we recommend the chequer plate lid option which is specially designed to provide increased protection. 70MM ALUMINIUM HONEYCOMB CEILING PANEL Astra WALL PANELS AND SAMPLES Ceiling Assessment Criteria The ACS-ALU70 panels are well suited to semi-conductor, aerospace, optical and high-technology applications, with zero out-gassing and a durable ESD or NSD roller-coated paint finish. • Construction phase access • • inches mm inches kg lb 1200 47 1/4 2980 117 5/16 29.36 65.73 ACS-ALU12-1200-3840-17-OE-ST05-ST05 1200 47 1/4 3840 151 3/16 37.83 83.40 We welcome visitors to our showroom to discuss our product ranges or, alternatively, we can arrange a site presentation, complete with samples and ceiling displays. Panel selection • mm ACS-ALU06-1200-2980-17-OE-ST05-ST05 In addition, we have full-size ceiling display stands that demonstrate the integration of our products, including ceiling systems, cleanroom lighting and filtration products. Landing zones • Weight High traffic areas • Max. Length Designated access routes • Width Operational facility access A standard range of panel sizes available, however other sizes can be custom made to order. Product Code We have a wide range of ceiling grid and ceiling panel samples available in presentation boxes, as shown below - please contact the sales office to request your sample. Panel protection Simple to install with minimal labor requirements on site, the ACS-ALU70 panels together with the ACS range of ceiling grid systems provide a cost effective, highly durable and low maintenance ceiling system. Technical Data • Face - 0.5mm (25 gauge) thick steel material sheet on both sides • Core - 49mm (1-15/16”) thick aluminium material honeycomb • Adhesive Consideration must be given to the usage of walkable ceiling panels, covering both construction and operation of the facility, in order to maintain the integrity and life expectancy of the ceiling. We recommend undertaking an assessment to identify walkways, hightraffic areas and landing zones to select the correct panel specifications. A detailed understanding of the construction process and close interaction with the installation team are important to identify any specific requirements, such as ladder use or access platforms. Additional details such as temporary panel protection can be incorporated into the panel selection process. - Thermosetting epoxy adhesive • Outgassing - Zero out-gassing The chequer plate finish is available for the 25mm, 30mm, 50mm and 70mm ACS ceiling panels. Point Load Test ACS-ALU70-1189-1189-17-FE-ST05-ST05 Dimensions: 1189mm x 1189mm (46 13/16” x 46 13/16”) Depth: 70mm (2 3/4”) Core: Aluminium honeycomb Top Skin: Steel 0.5mm Bottom Skin: Steel 0.5mm LOAD DEFLECTION (N) (kg) (lb) (mm) (inches) 1,000 102 225 0.62 0.0244 2,000 204 450 0.94 0.0370 3,000 306 675 1.24 0.0488 Test Method: The panel is subjected to load through a 70mm x 190mm rectangle indenter via a hydraulic cylinder at the centre of the panel. Panel Joining Extrusion Panel End Extrusion Panel Corner Extrusion *contact our sales office for a copy of the brochure. 12 13

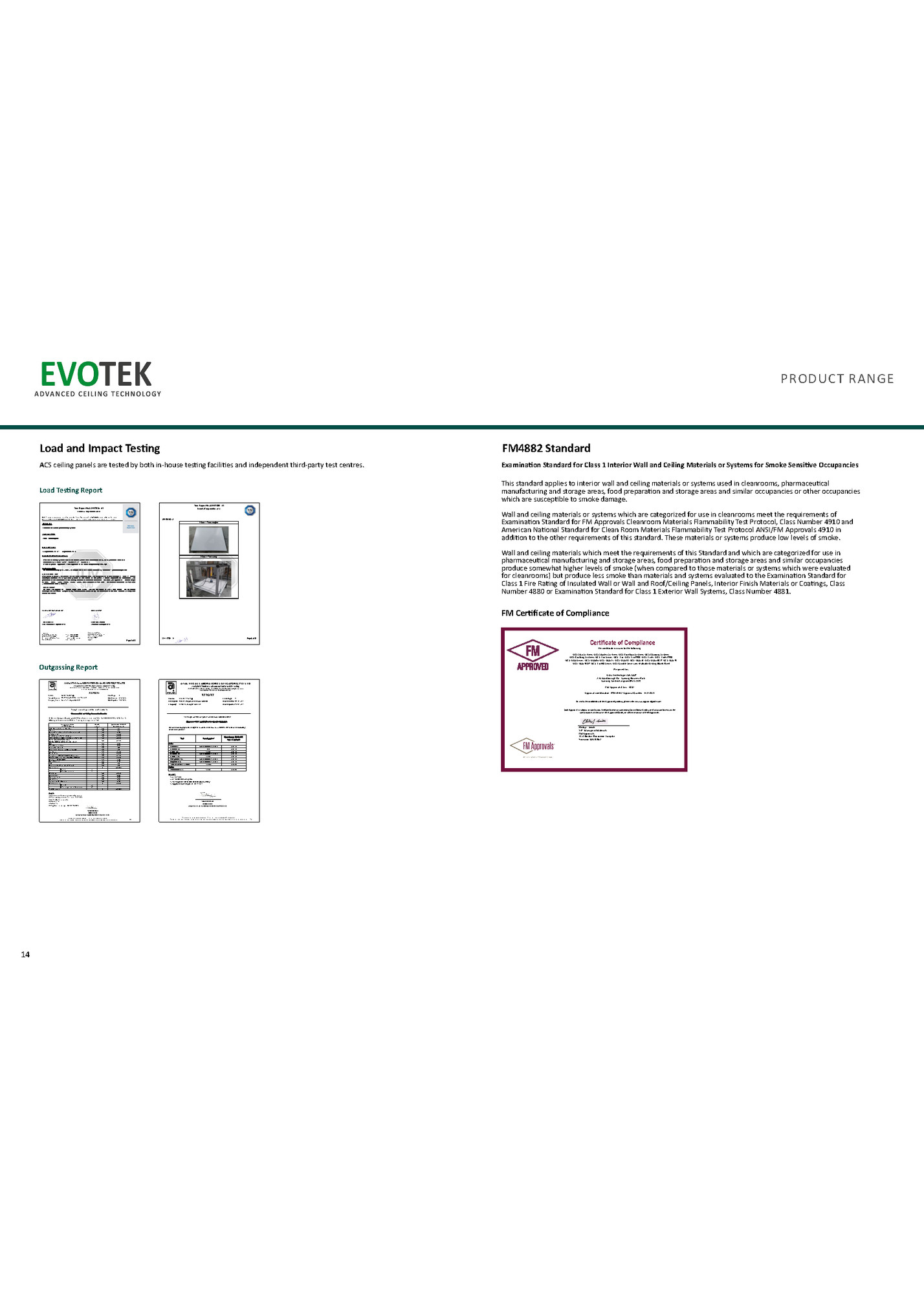

PRODUCT RANGE CLEAN SYSTEMS Load and Impact Testing FM4882 Standard ACS ceiling panels are tested by both in-house testing facilities and independent third-party test centres. Examination Standard for Class 1 Interior Wall and Ceiling Materials or Systems for Smoke Sensitive Occupancies Load Testing Report This standard applies to interior wall and ceiling materials or systems used in cleanrooms, pharmaceutical manufacturing and storage areas, food preparation and storage areas and similar occupancies or other occupancies which are susceptible to smoke damage. Dated 27 September 2019 EVOClean MODULAR CEILING SYSTEM FOR CLEAN AND STERILE ENVIRONMENTS The EVOClean is a non-walk-on suspended ceiling system designed specifically for cleanroom applications. Wall and ceiling materials or systems which are categorized for use in cleanrooms meet the requirements of Examination Standard for FM Approvals Cleanroom Materials Flammability Test Protocol, Class Number 4910 and American National Standard for Clean Room Materials Flammability Test Protocol ANSI/FM Approvals 4910 in addition to the other requirements of this standard. These materials or systems produce low levels of smoke. Dated 27 September 2019 Note: This report is issued subject to the Testing and Certification Regulations of the TÜV SÜD Group and the General Terms and APPENDIX A Conditions of Business of TÜV SÜD Malaysia Sdn Bhd. In addition, this report is governed by the terms set out within this report. Photo 1: Test Samples SUBJECT: Load test for 50mm panel ceiling system. TESTED FOR: Astra Technologies DATE OF TEST Suitable for both negative and positive pressure regimes, sterile and non-sterile environments, the EVOClean is the opportune solution for cleanrooms, laboratories, research centres and healthcare applications. The integrated LED lighting results in a completely flush finish for easy cleaning, with the absence of grooves and crevices preventing any build up of dirt and risk of contamination. Wall and ceiling materials which meet the requirements of this Standard and which are categorized for use in pharmaceutical manufacturing and storage areas, food preparation and storage areas and similar occupancies produce somewhat higher levels of smoke (when compared to those materials or systems which were evaluated for cleanrooms) but produce less smoke than materials and systems evaluated to the Examination Standard for Class 1 Fire Rating of Insulated Wall or Wall and Roof/Ceiling Panels, Interior Finish Materials or Coatings, Class Number 4880 or Examination Standard for Class 1 Exterior Wall Systems, Class Number 4881. 6 September 2019 / 17 September 2019 DESCRIPTION OF SAMPLES Photo 2: Test Setup One unit of ceiling system said to be model: 50mm thick aluminium core with 0.5mm thick steel skin aluminium (M Frame); Size: 1195mm (W) x 1195mm (H). (Refer to photo 1 appendix A and appendix B for client’s engineering drawing) TEST METHOD The aluminum ceiling grid which was suspended from a steel structure by means of 4 pieces hanger rod Uniform Load Test: One piece of panel was placed on the steel structure and was subjected to a load through a 70mm x 190mm rectangle indenter via a hydraulic cylinder at the center of the panel. A linear displacement transducer was positioned at the underside of the loading location to measure deflection. The load was applied in 1-minute steps of 500N, 1000N, 1500N, 2000N, 2500N, 3000N and released to zero load. The residual deflection at zero load was measured after 5 minutes. Test to Failure: The load was applied in 1-minute steps from 3500N with the increment of 500N until failure. The deflection readings are not taken. Subject to any abnormalities found during the increment of the load, the test will stop and record the result. Applications: • Regional Head Office: TÜV SÜD Asia Pacific Pte. Ltd. 1 Science Park Drive #02-01 Singapore 118221 Page 1 of 5 Page 3 of 5 221417589 – 01 Certificate of Compliance This certificate is issued for the following: ANALYTICAL LABORATORIES (SINGAPORE) PTE LTD Analytical Chemists; Environmental and Materials Testing Analytical Chemists; Environmental and Materials Testing No.8, Kaki Bukit Place, Singapore 416186 Tel:67460886 Fax:67463830 Email: admin@analabs.com.sg CO. REG NO:197302347G GST REG NO:M2-0017430-5 REPORT No.8, Kaki Bukit Place, Singapore 416186 Tel:67460886 Fax:67463830 Email: admin@analabs.com.sg CO. REG NO:197302347G GST REG NO:M2-0017430-5 Lab No Total Pages : AC/EL/1458/15@ Date Received : 07/03/2015 Date Reported : 10/03/2015 To verify the availability of the Approved product, please refer to www.approvalguide.com. Said Approval is subject to satisfactory field performance, continuing Surveillance Audits, and strict conformity to the constructions as shown in the Approval Guide, an online resource of FM Approvals. The sample consisted of 5 pieces of Cleanroom Material marked: Cleanroom Wall and Ceiling Construction Materials The sample consisted of 5 pieces of Cleanroom Material marked: On Dynamic Headspace Outgassing via GC/MS analysis in accordance with Doc. No: 20800020-001 Rev. K Method, the following results were obtained. (Refer to chromatogram and spectra attached):Result, ng/cm² Nil Nil Nil Nil Nil Nil <1 <1 ≤ 1,100 Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil 2 Cleanroom Wall and Ceiling Construction Materials Specification 20401067 Rev.K (ng/cm²) ≤ 15 ≤ 15 ≤ 100 ≤ 1,000 ≤ 1,200 ≤ 4,000 Nil 1 1 ≤ 400 ≤ 250 ≤ 20 ≤ 30 ≤ 1,500 ≤ 1,000 ≤ 1,300 ≤ 3,000 ≤ 700 ≤ 100 ≤ 10 ≤ 10 ≤ 20,000 ≤ 1,250 ≤ 400 ≤ 400 ≤ 200 ≤ 100 ≤ 1,000 ≤ 40,000 Nil Nil Nil Nil Nil 2 4 Phillip J. Smith VP - Manager of Materials FM Approvals 1151 Boston-Providence Turnpike Norwood, MA 02062 On Ion Chromatographic (IC) analysis in accordance with Doc. No. 20800012-001 method, the following results were obtained:- Test Result, µg/cm² Anion Fluoride, F Chloride, Cl Nitrite, NO₂ Bromide, Br Nitrate, NO₃ Phosphate, PO₄ Sulphate, SO₄ Total of seven (7) Anions Cation Ammonium, NH₄ Specification 20401067 Rev. K (µg/cm²) Not Detected ( < 0.01 ) 0.01 < 0.01 Not Detected ( < 0.01 ) < 0.01 Not Detected ( < 0.01 ) Not Detected ( < 0.01 ) < 0.03 ≤ 0.10 ≤ 0.10 ≤ 0.10 ≤ 0.10 ≤ 0.10 ≤ 0.10 ≤ 0.10 ≤ 0.20 < 0.01 ≤ 0.20 Remarks: 1) < Less than 2) ≤ Smaller than or equal to 3) The sample was rinsed with DI water prior to testing. 4) Supplement to test report, AC/EL/1458/15. 1) The above results were expressed as Hexadecane. 2) The outgassing test was conducted on 10/03/2015. 3) ≤ Smaller than or equal to 4) > Greater than 5) < Less than 6) Supplement to test report, AC/EL/1458B/15. The integrated lighting utilises advanced LED technology, these luminaires offer market-leading performance which significantly reduces the lifetime cost of ownership. SIM KOK HAI DIRECTOR ANALYTICAL LABORATORIES (S) PTE LTD SIM KOK HAI DIRECTOR ANALYTICAL LABORATORIES (S) PTE LTD This report shall not be reproduced except in full, without the written approval of the laboratory. For electronically transmitted report, its results contained therein shall be traceable to the original report bearing the manuscript signature. Pg1 This report shall not be reproduced except in full, without the written approval of the laboratory. For electronically transmitted report, its results contained therein shall be traceable to the original report bearing the manuscript signature. EVOSmart MODULAR CEILING SYSTEM FOR COMMERCIAL APPLICATIONS The EVOSmart is a modular ceiling system with standard grid dimensions and components. The flexibility of the system is advantageous in the design of commercial applications and the use of standard components results in an economical solution for installations large or small. Remarks: Pg1 Applications: • Commercial • Industrial • Hospitals • Laboratories • Research centres • 14 LED technology with an innovative modular ceiling concept. FM Approvals Class: 4882 :1 Description : One (1) sample of Cleanroom Material : Astra Technologies UK LLP Astra Technologies UK LLP 23A Marlborough Rd., Lancing Business Park, Lancing, United Kingdom BN15 8TR Approval Identification: PR459442 Approval Granted: 4/22/2021 REPORT Total Pages :6 Date Received : 07/03/2015 Date Reported : 10/03/2015 Company Sulfur Dioxide & Carbon Disulfide Siloxane Amines (Tributylamine, N-phenyl benzenamine) Ethyl Hexanol Acrylic Acid and Methacrylic Acid 2-Phenyl 2-Propanol (Dimethyl Benzene Methanol) Methacrylates & Alkyl Acrylates (HEMA, IBOMA, HPMA, Octyl Acrylate) BHT 2-Ethyl Hexanoic Acid Amides (Acrylamide) Organo Sulfur Compounds (Benzothiazole) Caprolactam Benzoic Acid Acetophenone (DMAP, CHAP) & Derivatives Polyglycol, Dimethacrylate (TGDMA, PhDMA) Other Esters (DOP, DBP) Dioctyl Sebacate Sulfur Organometallics (Tributyltin Chloride) Hydrocarbons Hexane Other Hydrocarbons Other Acids Alcohols, >C7 Hydroxybenzenes Glycol Ethers N-substituted Pyrrolidinone Other Compounds Decanal Other compounds not listed above Total Outgassing A unique* design, combining advanced Prepared for: ANALYTICAL LABORATORIES (SINGAPORE) PTE LTD Compounds detected via DHS Outgassing expectations. ACS Stud Systems, ACS Studless Systems, ACS Frontload Systems, ACS Cladding Systems, ACS Caulking Systems, ACS-T56 Series, ACS-T56, ACS-T56 PRO, ACS-T56N, ACS-T56N PRO, ACS-ALU Series, ACS-ALU06, ACS-ALU25, ACS-ALU30, ACS-ALU50, ACS-ALU50CP, ACS-ALU70, ACS-ALU70CP, ACS T56HD Series, ACS Gridlite Series and Walkable Ceiling Blank Panel Outgassing Report Lab No : AC/EL/1458B/15@ Sample Received : One (1) sample of Cleanroom Material Company Name : Astra Technologies UK LLP Biotechnology Aseptic suites EVOTEK ceiling systems exceed all Pharmaceutical • Hafiz Bin Ahmad Assistant Manager (RI) We understand the demands of advanced technology facilities and Sterile environments • • SIGNATORY Tan Quan He Lab Associate Engineer (RI) Cleanrooms • FM Certificate of Compliance TESTED/PREPARED BY Phone : +603 7859 8822 Fax : +603 7859 8824 E-mail: enquiry@tuv-sud.my www.tuv-sud.my CLEAN SYSTEMS Test Report No.221417589 - 01 Test Report No.221417589 - 01 Laboratory: TÜV SÜD Malaysia Sdn Bhd No. 18, Jalan Astaka U8/82, Bukit Jelutong, 40150 Shah Alam, Selangor Malaysia. Astra CERTIFICATIONS Healthcare applications The flush ceiling system is easy to clean requiring minimal maintenance, which, together with world class LED efficiencies, results in a reduced lifetime cost of ownership. *pat pending www.astracleansystems.co.uk 15

CLEAN SYSTEMS WORLD CLASS WORLDWIDE Kingsway House, 23A Marlborough Road, Lancing, West Sussex, BN15 8TR, United Kingdom t: +44 (0) 1903 764 736 f: +44 (0) 1903 764 761 e: sales@astracleansystems.com w: www.astracleansystems.com Rev 090425

Fleepit Digital © 2021