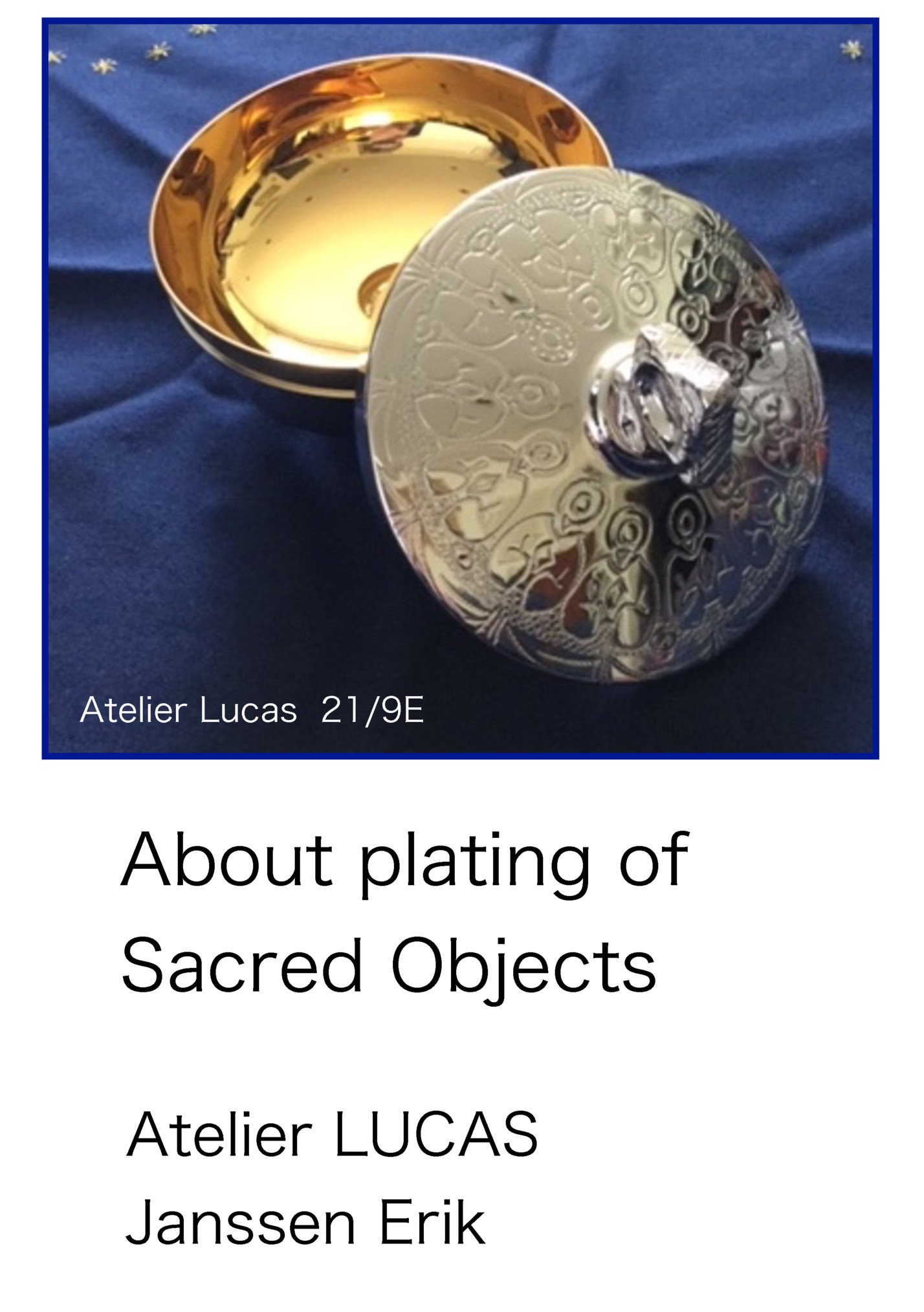

About plating of Sacred Objects Atelier LUCAS Janssen Erik

Atelier LUCAS 670−0071 Himeji city Mitachi Kita 2-1-16 Japan Mail vitrea@mac.com Mobile 090-7344-3560 FAX 079-297-8609

It has been more than 120 years since electroplating technology was introduced to Japan. As we know today, nickel plating is done using direct current. It has been nearly 100 years since nickel plating was first used for industrial purposes. The development of plating has been remarkable, and improvements in technology, equipment, process control, quality control, etc. have resulted in improved corrosion protection and appearance. The direct cause of this is the widespread use of copper, nickel, chromium, zinc, cadmium, and other light plating.

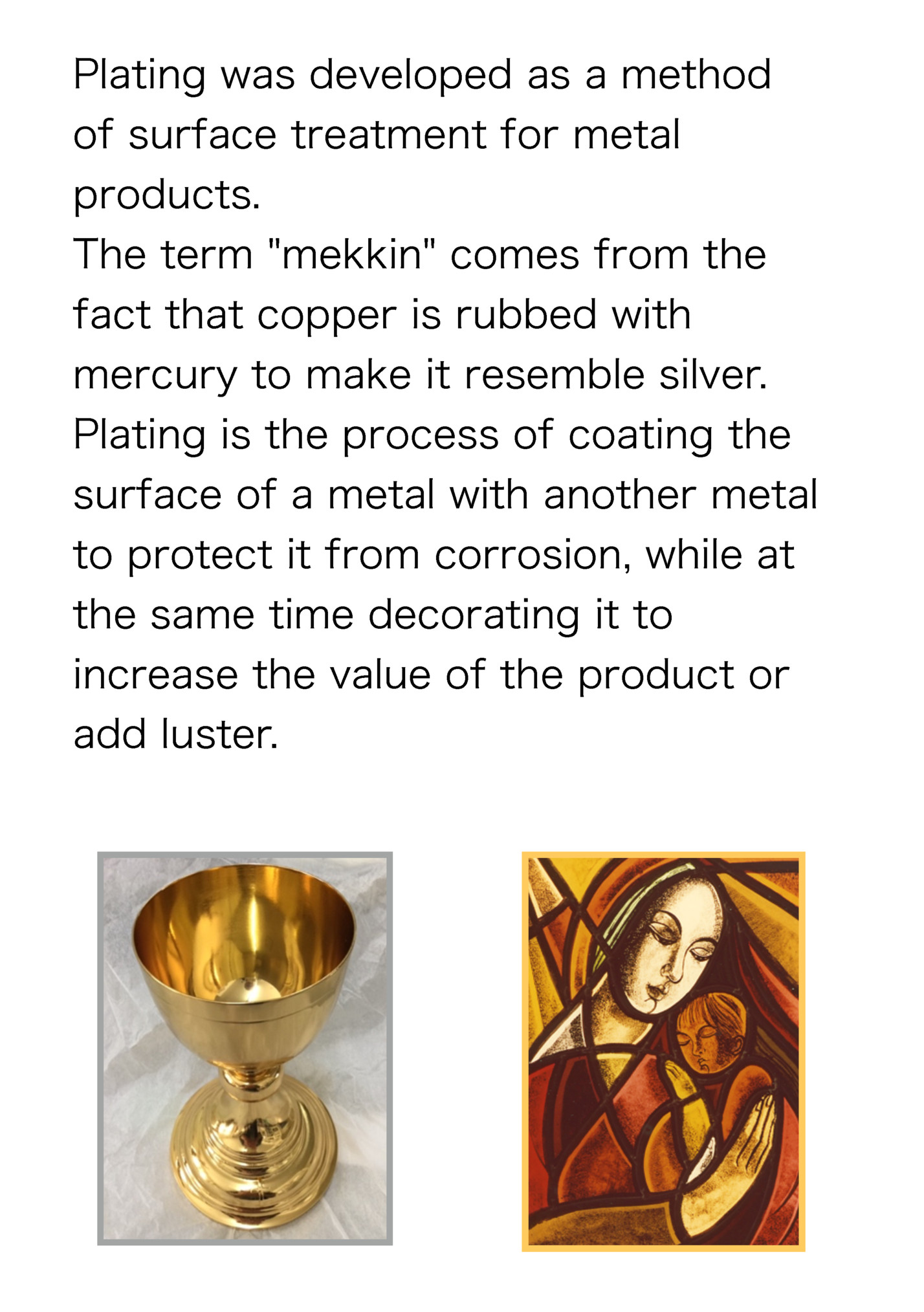

of surface treatment for metal products. The term "mekkin" comes from the fact that copper is rubbed with mercury to make it resemble silver. Plating is the process of coating the surface of a metal with another metal to protect it from corrosion, while at the same time decorating it to increase the value of the product or add luster.

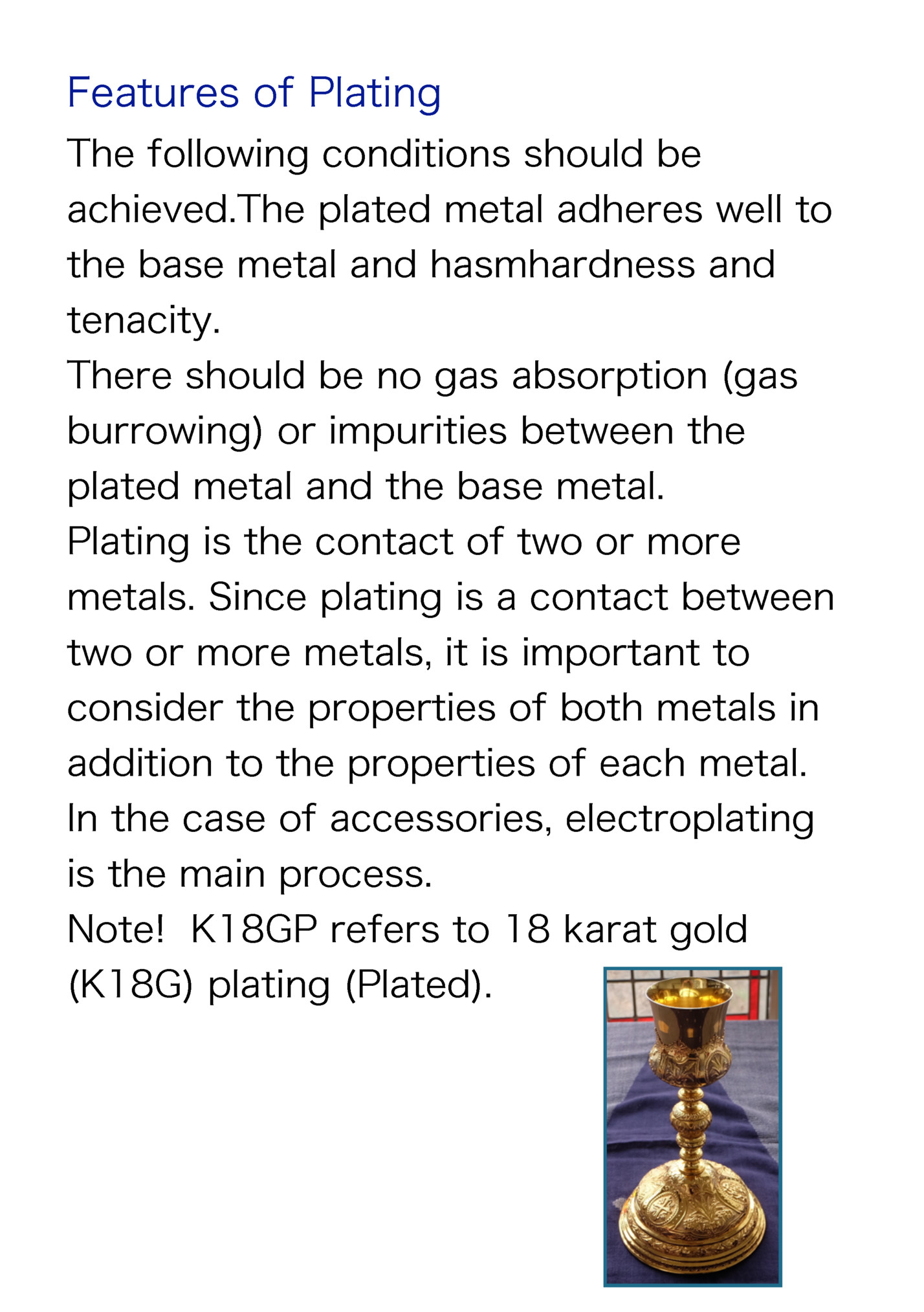

The following conditions should be achieved.The plated metal adheres well to the base metal and hasmhardness and tenacity. There should be no gas absorption (gas burrowing) or impurities between the plated metal and the base metal. Plating is the contact of two or more metals. Since plating is a contact between two or more metals, it is important to consider the properties of both metals in addition to the properties of each metal. In the case of accessories, electroplating is the main process. Note! K18GP refers to 18 karat gold (K18G) plating (Plated).

* Electroplating is the process of using electrical energy to create a film of another metal on a base metal. *Chemical plating (electroless plating) * Chemical change is used to create a film of another metal on another metal. * Vapor deposition plating. Evaporation plating: A film of another metal is created by spraying vapor of another metal the base metal. *Hot-dip plating: The base metal is immersed in molten metal to form a metal film.

1. base metal (product to be plated) (degreasing, acid washing, water washing) 2. polishing (barrel, buffing) (water wash) 3. solvent degreasing (surface cleaning) (water rinse) 4. acid treatment (surface cleaning, rust removal) (water rinse, neutralization, water rinse, drying) 5.Copper plating (for anticorrosion, plating to stop rough metal surface) (water rinse) 6. nickel plating (brightening, hardening of substrate) (water rinse) 7. precious metal plating (finish plating)

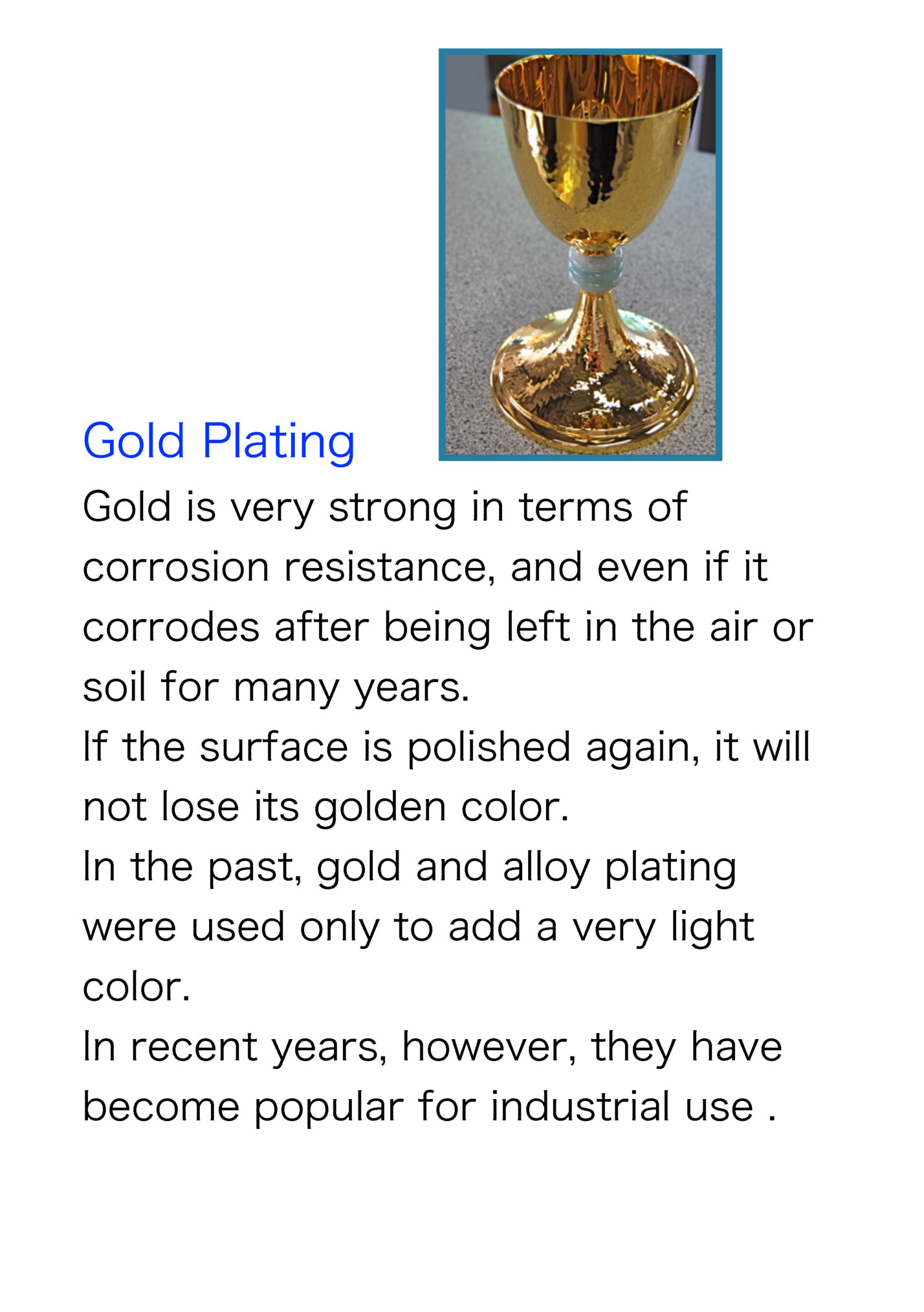

Gold is very strong in terms of corrosion resistance, and even if it corrodes after being left in the air or soil for many years. If the surface is polished again, it will not lose its golden color. In the past, gold and alloy plating were used only to add a very light color. In recent years, however, they have become popular for industrial use .

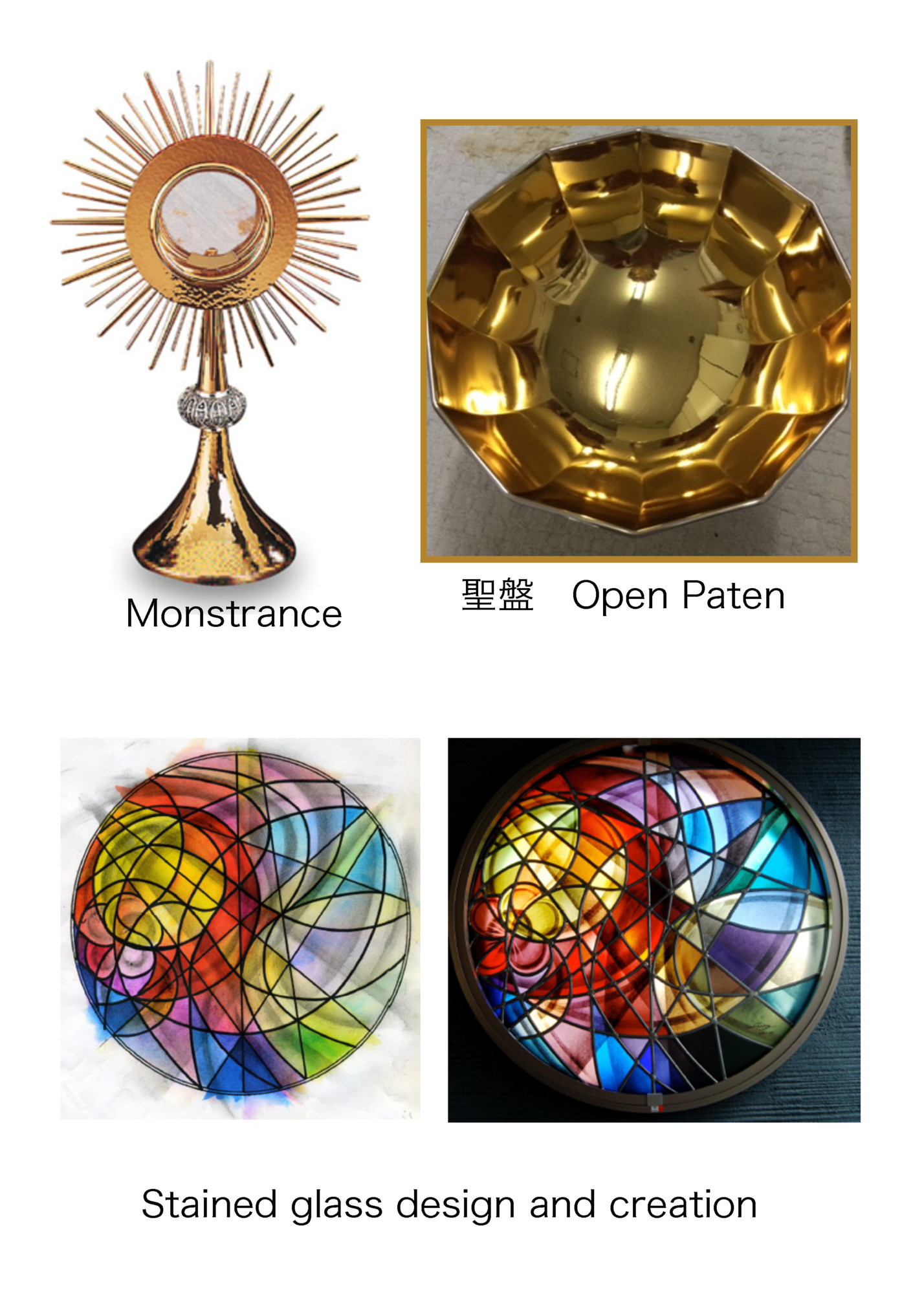

聖盤 Open Paten Stained glass design and creation

Fleepit Digital © 2021