Carrry bags making project Details. Biodegradable (adjective of a substance or object) : capable of being decomposed by bacteria or other living organisms and thereby avoiding pollution lick to प्राकृतिक परिस्थितियों में अपघटनीय पदािथ The Problem (read Market) Conventional carry bags have been banned Central Government has made it mandatory to stop use of single use plastics by February 2022. Supply chain system of the product is well established Customers are unable to change their habit of using carry bag as its very convenient So MSME has an opportunity here,

End No of uses are there with the Bio-Degradable Plastic Carry bags Agriculture Warp sheets Dinning warp sheets Seed packing bags Food grades items packings Garbage bags Exports packings etc. Go for green India soon We have plans to facilitate & promote good numbers of units in India thus becoming the pioneer country Pollution free and green country “पहला हमेशा पहला”

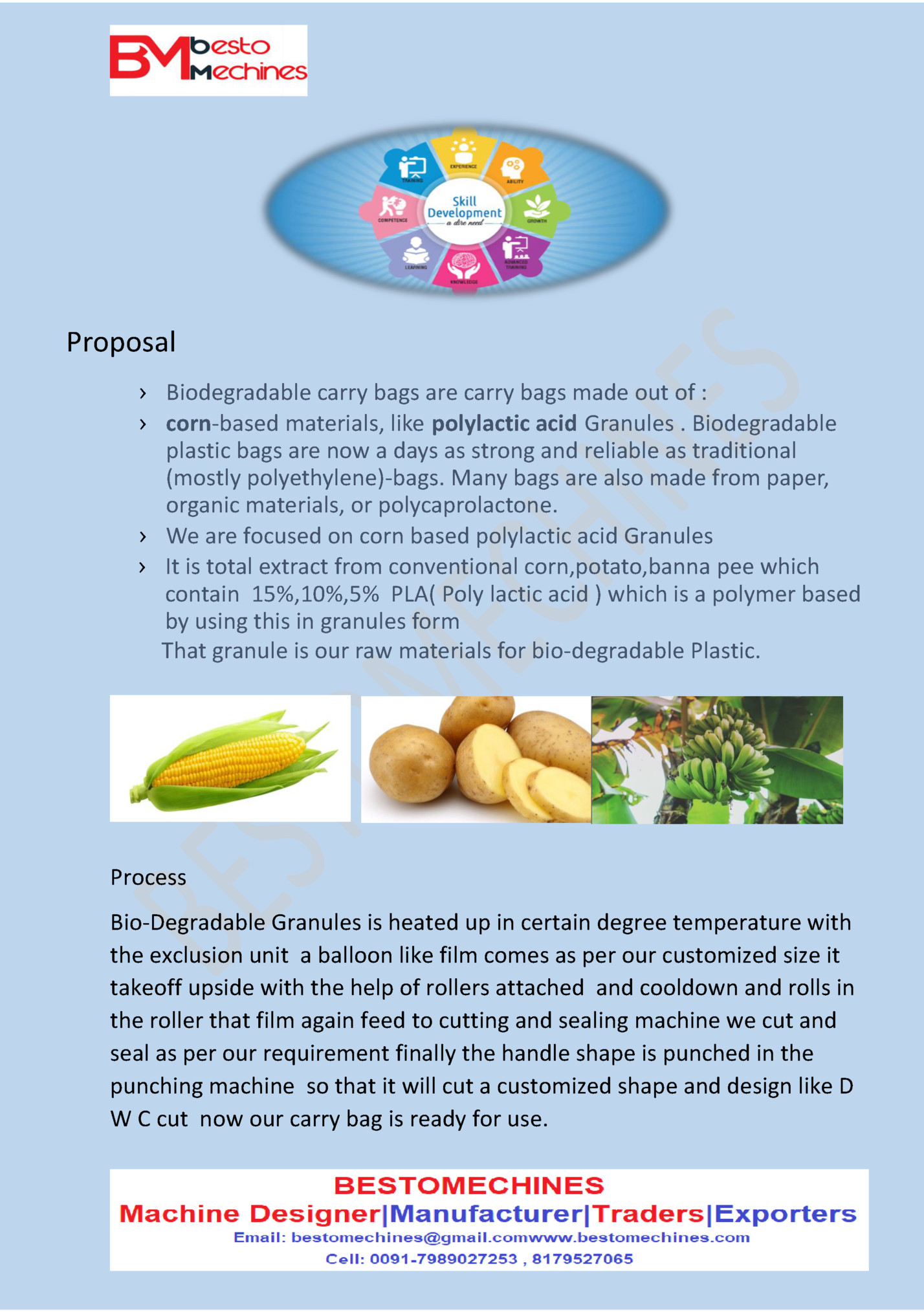

› Biodegradable carry bags are carry bags made out of : › corn-based materials, like polylactic acid Granules . Biodegradable plastic bags are now a days as strong and reliable as traditional (mostly polyethylene)-bags. Many bags are also made from paper, organic materials, or polycaprolactone. › We are focused on corn based polylactic acid Granules › It is total extract from conventional corn,potato,banna pee which contain 15%,10%,5% PLA( Poly lactic acid ) which is a polymer based by using this in granules form That granule is our raw materials for bio-degradable Plastic. Process Bio-Degradable Granules is heated up in certain degree temperature with the exclusion unit a balloon like film comes as per our customized size it takeoff upside with the help of rollers attached and cooldown and rolls in the roller that film again feed to cutting and sealing machine we cut and seal as per our requirement finally the handle shape is punched in the punching machine so that it will cut a customized shape and design like D W C cut now our carry bag is ready for use.

Raw materials are use made with PLA (Poly lactic acid) is a thermoplastic polyester formally obtained by condensation of lactic acid with loss of water. It can also be prepared by ring-opening polymerization of lactide PLA has become a popular material due to it being economically produced from renewable resources. In 2010, PLA had the second highest consumption volume of any bioplastics of the world The monomer is typically made from fermented plant starch such as from corn, potato, banana peal cassava, sugarcane or sugar beet pulp. PLA (Poly Lactic Acid) › PLA (polylactic acid) is typically made from the sugars in corn starch, Potato,bannan pee, sugar cane It is biodegradable, contain Polymer carbon-neutral and edible. To transform corn into plastic, corn

components break down into starch, protein, and fiber. Uses of Bioplastics › Bioplastics are currently used in disposable items like packaging, containers, straws, bags and bottles, and in non-disposable carpet, plastic piping, phone casings, 3-D printing, car insulation and medical implants Manufacturing process Biodegradable carry bags

2000 Sqft of buildup area Height of the building about 20 feet for excluder machine. 45 kv industrial power supply line. Water line for cooling tower very little amount only. Fully ventilated with air flow freely. Two No of fire cylinders for fire fighting.as per the department guidelines First Aid kit Labor aprons as per the labor department guidelines.

1) Extruder Machine (45mm Bio-degradable. 32Nip Roll) 2) High Speed Cutting & Sealing Machine Double Line Loading System 3) Heavy Duty Punching Machine 4) Cooling Tower 5) Heavy Duty Air Compressor 6) Printing machine.

(45mm Bio-degradable. 32Nip Roll) Extruder Machine Convert Granules into film in some Temperature as per the setting Size and thickness (microns). that film will blow upside up to 16ft height starts rolling with the rollers arrange upside and Cool down, Online Logo printer, Prints The logo, company name, licence No Up to 4 inches and cover rollers and form roller of the film Machine will produce 60 Kgs per hour Capacity High Speed Cutting & Sealing Machine Double Line Loading System › High-speed cutting and sealing will cut and seal the cover as per our requirement and size with auto counting as per sitting and puts a side after count complete with a conveyer belt attached to it at a time 6 rolls of 30 kg each can be load with double line fitting after count a bunch. Of carry bags customize count will move as side then that bunch is feed to punching machine

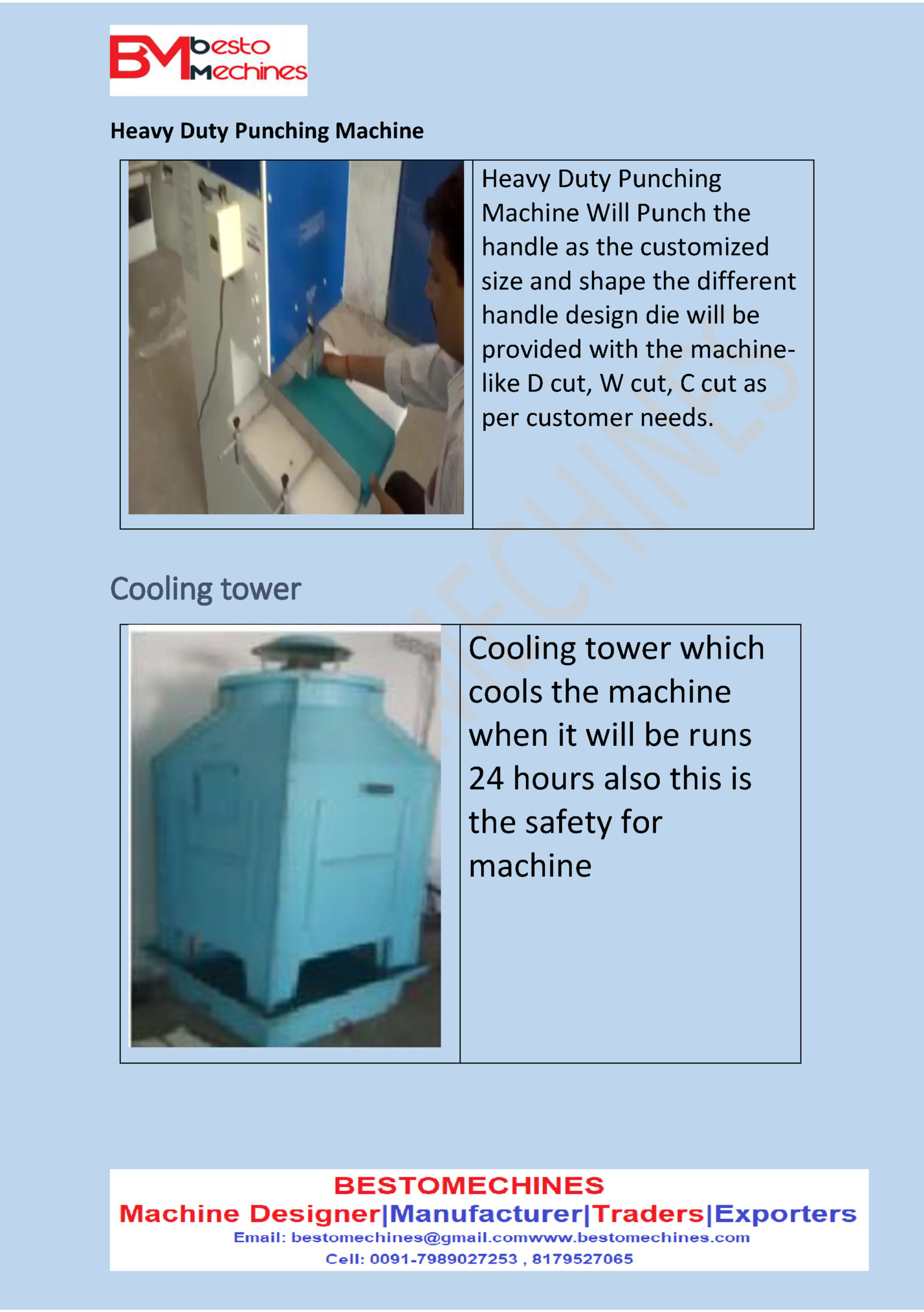

Heavy Duty Punching Machine Will Punch the handle as the customized size and shape the different handle design die will be provided with the machinelike D cut, W cut, C cut as per customer needs. Cooling tower Cooling tower which cools the machine when it will be runs 24 hours also this is the safety for machine

Fleepit Digital © 2021